- Blogs

- Can Foam Pipe Insulation Be Used Underground?

Can Foam Pipe Insulation Be Used Underground?

If you are looking for a way to protect your pipes from freezing, bursting, or losing heat, you might be wondering if foam pipe insulation can be used underground. Foam pipe insulation is a popular and cost-effective option for insulating pipes in various applications, such as plumbing, heating, and cooling systems. But can it withstand the harsh conditions of being buried underground?

The answer is yes but with some caveats. Foam pipe insulation can be used underground, but it needs to be properly installed and protected from moisture, rodents, and other potential hazards.

In this article, we will explain how to use foam pipe insulation underground, what are the benefits and drawbacks of doing so, and what are some alternatives you can consider.

How to Use Foam Pipe Insulation Underground

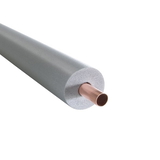

Foam pipe insulation is usually made of polyethene or polyurethane, which are flexible and lightweight materials that can conform to the shape of the pipes. Foam pipe insulation comes in different forms, such as pre-slit tubes, rolls, or sheets, and can be cut to fit the desired length and diameter of the pipes.

To use foam pipe insulation underground, you need to follow these steps:

To use foam pipe insulation underground, you need to follow these steps:

- Prepare the trench. You need to dig a trench that is deep enough to prevent the pipes from freezing, which depends on the climate and the soil conditions of your area. The trench should also be wide enough to accommodate the pipes and the insulation, leaving some space for backfilling. You can use a shovel or a trencher to dig the trench, and make sure to remove any rocks, roots, or debris that could damage the pipes or the insulation.

- Lay the pipes. You need to lay the pipes in the trench, following the design and the specifications of your system. You can use copper, steel, or plastic pipes, depending on the type and the pressure of the fluid that will flow through them. You should also install any fittings, valves, or joints that are required for your system, and make sure that the pipes are leak-free and secure.

- Wrap the pipes with foam insulation. You need to wrap the pipes with foam insulation, covering them completely and leaving no gaps or exposed areas. You can use pre-slit tubes that can be snapped over the pipes, or rolls or sheets that can be wrapped around the pipes and secured with tape or adhesive. You should also insulate any fittings, valves, or joints that are part of the system, and make sure that the insulation is snug and tight around the pipes.

- Protect the insulation with a vapour barrier. You need to protect the insulation with a vapour barrier, which is a layer of material that prevents moisture from penetrating the insulation and reducing its effectiveness. Moisture can cause the insulation to deteriorate, mould, or rot, and can also freeze and expand, causing the pipes to burst. You can use a plastic sheet, foil wrap, or waterproof tape to cover the insulation and create a vapour barrier. You should also seal any seams or joints with tape or adhesive, and make sure that the vapor barrier is intact and continuous.

- Backfill the trench. You need to backfill the trench with soil, sand, or gravel, covering the pipes and the insulation completely. You should avoid using any sharp or heavy materials that could puncture or compress the insulation or the pipes. You should also tamp down the backfill to eliminate any air pockets or voids that could allow water to accumulate or freeze. You can use a tamper or a compactor to compact the backfill and make sure that the surface is level and smooth.

Benefits and Drawbacks of Using Foam Pipe Insulation Underground

Using foam pipe insulation underground has some benefits and drawbacks that you should consider before deciding to do so. Here are some of them:

Benefits

- It reduces heat loss and saves energy. Foam pipe insulation can reduce the heat loss from the pipes by up to 80%, depending on the thickness and the R-value of the insulation. This means that the fluid in the pipes will maintain its temperature and flow more efficiently, reducing the energy consumption and the cost of operating the system.

- It prevents freezing and bursting. Foam pipe insulation can prevent the pipes from freezing and bursting in cold climates, by keeping the fluid in the pipes above the freezing point. This can prevent costly and dangerous damage to the pipes and the system, as well as the surrounding structures and environment.

- It is easy to install and affordable. Foam pipe insulation is easy to install, as it can be cut and fitted to the pipes with simple tools and materials. It is also affordable, as it is widely available and has a low initial cost compared to other types of insulation.

Drawbacks

- It is vulnerable to moisture and rodents. Foam pipe insulation is vulnerable to moisture and rodents, which can penetrate the insulation and cause it to deteriorate, mould, or rot. Moisture can also freeze and expand, causing the pipes to burst. Rodents can also chew or gnaw on the insulation, exposing the pipes and creating gaps or holes. To prevent these problems, you need to protect the insulation with a vapour barrier and a rodent-proof barrier, such as a metal mesh or a wire cage.

- It has a limited lifespan and requires maintenance. Foam pipe insulation has a limited lifespan, as it can degrade over time due to exposure to moisture, rodents, chemicals, or UV rays. It also requires regular maintenance, such as checking for leaks, damages, or signs of deterioration, and replacing or repairing the insulation as needed. You may also need to excavate the trench to access the pipes and the insulation, which can be labour-intensive and disruptive.

- It is not suitable for high-temperature or high-pressure applications. Foam pipe insulation is not suitable for high-temperature or high-pressure applications, as it can melt, deform, or rupture under extreme conditions. For example, foam pipe insulation is not recommended for steam pipes, as the steam can reach temperatures above 100°C and pressures above 15 psi, which can exceed the limits of the insulation. You may need to use other types of insulation, such as fibreglass, mineral wool, or ceramic, for these applications.

Alternatives to Using Foam Pipe Insulation Underground

If you are looking for alternatives to using foam pipe insulation underground, you may consider some of these options:

If you are looking for alternatives to using foam pipe insulation underground, you may consider some of these options:

- Use a different type of insulation. You can use a different type of insulation that is more resistant to moisture, rodents, or high temperatures and pressures, such as fibreglass, mineral wool, or ceramic. These types of insulation have higher R-values and longer lifespans than foam pipe insulation, but they are also more expensive and difficult to install.

- Use a pre-insulated pipe system. You can use a pre-insulated pipe system, which is a pipe that is already insulated and protected by a durable outer casing, such as steel, plastic, or concrete. These systems are designed to withstand underground conditions and provide optimal performance and reliability. However, they are also more costly and complex to install and maintain than foam pipe insulation.

- Use a heat trace system. You can use a heat trace system, which is a system that uses electric cables or wires to heat the pipes and prevent them from freezing. These systems are controlled by thermostats or sensors that regulate the temperature and the power supply of the cables or wires. They are effective and convenient, but they also require a constant source of electricity and can pose a fire or shock hazard if not installed or used properly.

Frequently Asked Questions

Q: Can foam pipe insulation be used underground?

A: Yes, foam pipe insulation can be used underground as long as it is specifically designed and labelled for underground use. It is important to use insulation that is suitable for underground conditions to prevent moisture absorption and degradation. Polyethylene foam insulation, such as Armaflex, is a common choice for underground pipe insulation due to its resistance to water and moisture.

Q: What is underground pipe insulation?

A: Underground pipe insulation is a type of insulation designed to be used on pipes that are buried underground. It is specifically formulated to withstand the unique conditions found underground, such as moisture, soil pressure, and temperature fluctuations. This type of insulation helps to prevent heat loss, protect the pipes from corrosion, and reduce the risk of condensation forming on the exterior of the pipes.

Q: What is pipe lagging and how is it different from underground pipe insulation?

A: Pipe lagging and underground pipe insulation are similar in that they both provide thermal insulation for pipes. However, pipe lagging typically refers to insulation used on exposed pipes, while underground pipe insulation is specifically designed for buried pipes. Pipe lagging can be made of various materials, such as closed-cell foam, and is often used to insulate water pipes in residential and commercial buildings.

Q: What is the recommended thickness for underground pipe insulation?

A: The recommended thickness for underground pipe insulation can vary depending on factors such as the depth of burial, the type of soil, and the temperature variations in the region. However, a common recommendation is to use insulation with a minimum thickness of 25mm for underground pipes. Thicker insulation may be necessary in areas with extreme temperatures or high levels of groundwater.

Q: What are the key features of polyethene foam insulation for underground pipes?

A: Polyethylene foam insulation, such as Armaflex, is a popular choice for underground pipe insulation due to its resistance to water, moisture, and heat transfer. It is a closed-cell foam with excellent thermal insulation properties, making it suitable for underground use. Additionally, polyethene foam insulation helps to prevent corrosion under insulation and reduce the risk of condensation on the pipes.

Conclusion

Foam pipe insulation can be used underground, but it needs to be properly installed and protected from moisture, rodents, and other potential hazards. It can provide some benefits, such as reducing heat loss, preventing freezing and bursting, and saving energy, but it also has some drawbacks, such as being vulnerable to moisture and rodents, having a limited lifespan, and requiring maintenance.

You may also consider some alternatives, such as using a different type of insulation, a pre-insulated pipe system, or a heat trace system, depending on your needs and preferences.

We hope this article has answered your question of “Can Foam Pipe Insulation Be Used Underground?” and helped you make an informed decision. If you are looking for quality foam pipe insulation and other insulation products, you can visit our website at Buy Insulation Online, where you can find a wide range of options and prices to suit your needs. You can also contact us for any questions or inquiries, and we will be happy to assist you.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *