- Blogs

- Kingspan Kooltherm Pipe Insulation and BS5422: What You Need to Know

Kingspan Kooltherm Pipe Insulation and BS5422: What You Need to Know

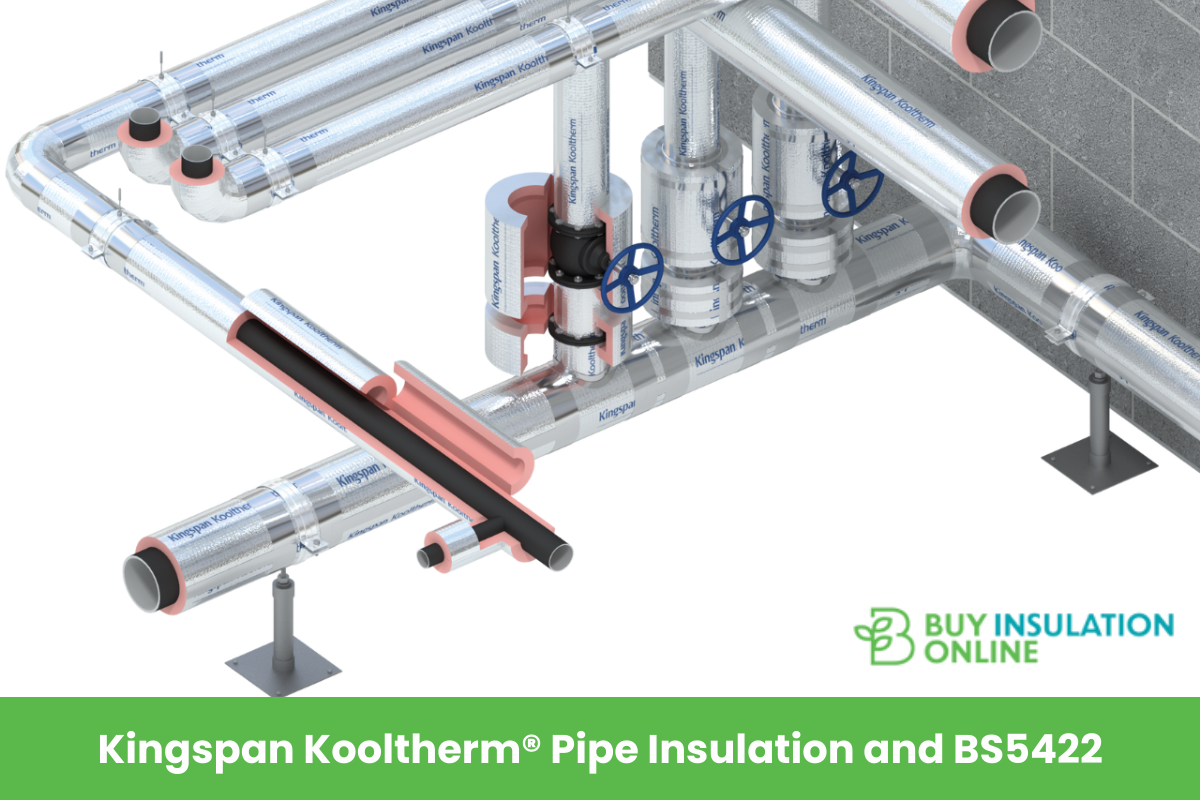

Pipe insulation is a vital part of any building system that involves the transport of fluids or gases. It can help you save energy, prevent condensation, protect pipes from corrosion, enhance fire safety, and improve acoustic performance. But how do you know which pipe insulation product is the best for your project?

In this article, we will introduce you to Kingspan Kooltherm® Pipe Insulation, a high-performance pipe insulation product that can meet the requirements of BS 5422, a widely used standard for specifying pipe insulation in the UK.

Kooltherm® Pipe Insulation and BS 5422: 2023

The British Standards Institution (BSI) has released the most recent edition of BS 5422: 2023 - (Thermal insulating materials for pipes, tanks, vessels, ducting, and equipment operating in the temperature range -40 °C to +700 °C - Method of specification).

This standard is the foundation of thermal insulation standards in the United Kingdom, establishing minimum levels of performance for various working scenarios. This is the first update since 2009, and the industry has been waiting for it for a long time.

BS 5422: 2023 makes numerous significant revisions that will impact the specification of Kingspan Kooltherm® Pipe Insulation.

Related Products

Major Changes

In summary,

- Tables within the standard have been simplified, with the removal of rarely used thermal insulation values and the elimination of separate tables for steel and copper pipes. These have been replaced by a "less than or equal to" value, which theoretically offers contractors only one table to refer to.

- References to fire response have been updated to reflect the requirement for Euroclass fire ratings, and the now-withdrawn national classification criteria have been removed. The prerequisites are now as follows:

- In buildings other than residences, the complete assembly of market-placed materials (whether faced or unfaced) must be class B-s3, d2 (European class) or better, according to BS EN 13501-1: 2018 (Fire classification of construction products and building elements - classification using data from reaction to fire tests).

- The total assembly of installed insulating materials (whether faced or unfaced) in houses must be class C-s3, d2 (European class) or better.

- The tables from the Energy Technology List (also known as Enhanced Capital Allowances) have now been added as extra enhanced tables within the standard.

- A district heating table based on 55 °C flow temperatures with far more stringent heat loss restrictions than existing tables has been added.

- Single-wall plastic pipes are now thought to have no insulative value.

Corrections to the Calculation Standard

It is important to note that the standard presently does not take into account the modifications to the BS EN ISO 12241: 2022 (Thermal insulation for building equipment and industrial facilities. Calculation rules) conventional calculation.

BS 5422: 2023 was released in accordance with the calculating standard's 2008 edition, rather than the newly announced 2022 edition. This was done to reduce delays, but it does mean that the standard will need to be adjusted in the future to account for these changes (Q3 2023 is mentioned). This standard change has a substantial impact on calculating thicknesses for condensation control and, when implemented, will result in some widespread thickness adjustments.

It is worth noting that the standard also includes the following reference in section 8.3.3, implying that the enhanced (Table B) shall be utilized for each applicable standard unless otherwise specified.

Minimum insulation thickness required to manage heat

Note: The relevant thicknesses defined in Tables 15–18 were calculated using the approach outlined in Annex A.

In the absence of particular specifier instructions, enhanced insulation thickness has been recorded from the legacy Energy Technology List / Capital Allowances levels and shall be as shown in Tables 15B, 16B, 17B, and 18B.

Insulation Thickness Tables

If the required performance standards are not clearly indicated in a specification, Kingspan Insulation Ltd recommends that contractors seek guidance.

Tables to meet the new BS 5422: 2023 criteria utilizing Kooltherm® Pipe Insulation are presented below, with the necessary A and B tables shown together for comparison.

The standard has deleted target W/m heat losses for pipe sizes larger than 273 mm OD and replaced it with the same thickness to be used as 273 mm OD.

Table 1 shows the recommended insulation thickness (mm) for Non-Domestic Hot Water (60 °C) and Low-Temperature Heating Service Areas (95 °C) to control heat loss.

Buy Kooltherm® Pipe Insulation

Heat gain and condensation thicknesses are combined below, with the most onerous thickness for each situation shown.

Table 2: Indicative insulation thickness (mm) necessary for cold and chilled water sources to control heat gain and condensation.

Table 19C now includes a new table for district heating systems. The compliance thicknesses are as follows.

It should be noted that this does not supersede the requirements of CIBSE CP1 (2020), and there may be additional requirements for CIBSE CP1 compliance.

Table 3: Indicative insulation thickness (mm) required for district heating to control heat loss.

Note: All of our tables have been computed in accordance with the new BS EN ISO 12241: 2022 standard.

What is BS 5422 and why is it important?

BS 5422: 2023 - (Thermal insulating materials for pipes, tanks, vessels, ductwork and equipment operating within the temperature range –40 °C to +700 °C – Method for specifying) is a standard that sets out the minimum requirements for the thermal performance, fire performance, and installation of pipe insulation materials. It also provides tables of recommended insulation thicknesses for different types of pipes, fluids, temperatures, and heat loss or condensation control objectives.

BS 5422 is important because it helps you choose the right pipe insulation product for your specific application and operating conditions. By following the guidance of BS 5422, you can ensure that your pipe insulation product meets the relevant regulations and standards, such as the Building Regulations Part L (Conservation of fuel and power), BS EN 12828 (Heating systems in buildings - Design for water-based heating systems), BS EN 14336 (Heating systems in buildings - Installation and commissioning of water-based heating systems), and BS 9999 (Fire safety in the design, management and use of buildings - Code of practice).

What is Kingspan Kooltherm® Pipe Insulation and What are its Benefits?

Kingspan Kooltherm® Pipe Insulation is a pipe insulation product made from rigid phenolic foam with a closed cell structure that minimises heat transfer and water vapour diffusion. It has a thermal conductivity as low as 0.025 W/m·K at 10 °C, which means it can achieve the same level of thermal performance as other insulation materials with much thinner thicknesses. This can result in significant space and cost savings, as well as reduced carbon emissions.

Kingspan Kooltherm® Pipe Insulation also has excellent fire performance. It is classified as Euroclass B-s1,d0 according to BS EN 13501-1: 2018 (Fire classification of construction products and building elements - Classification using data from reaction to fire tests), which means it has very limited contribution to fire spread and smoke production. It also meets the fire performance requirements of BS 5422: 2023 for both buildings other than dwellings and dwellings.

Kingspan Kooltherm® Pipe Insulation is compatible with BS 5422: 2023 and can be specified for various applications and operating conditions. The product has been tested and certified by various independent bodies, such as BBA, FM Approvals, LPCB, and BRE. It also comes with a range of factory-applied or site-applied facings and accessories to suit different installation requirements.

Here is a product example of Kingspan Pipe Insulation - Kooltherm Phenolic Pipe Insulation which is available with us at Buy Insulation online.

Kingspan Pipe Insulation - Kooltherm Phenolic Pipe Insulation

Kingspan Pipe Insulation, specifically their Kooltherm Phenolic Pipe Insulation, is a high-performance insulation material designed to provide exceptional thermal efficiency, fire resistance, and cost-effectiveness. Key features and benefits include:

Kingspan Pipe Insulation, specifically their Kooltherm Phenolic Pipe Insulation, is a high-performance insulation material designed to provide exceptional thermal efficiency, fire resistance, and cost-effectiveness. Key features and benefits include:

Thermal Performance:

- Kingspan Pipe Insulation boasts an impressive thermal conductivity of just 0.025 W/m·K, making it one of the most thermally efficient insulation materials available.

- Its low thermal conductivity allows for thinner insulation thicknesses, saving space in various applications.

Fire Performance:

- The insulation's phenolic lagging develops a thick carbonaceous layer when exposed to fire, limiting heat generation and slowing flame spread.

- Phenolic foam insulation is inherently difficult to ignite, enhancing fire resistance.

Moisture Resistance:

- The closed-cell structure of Kooltherm offers high resistance to moisture ingress and permeation, protecting pipes from corrosion and adverse reactions.

- It features an outer foil face vapor barrier that prevents moisture from reaching the core material.

Environmental Considerations:

- Kingspan pipe insulation is environmentally friendly, being CFC/HCFC-free and having a low Ozone Depletion Potential (ODP) and Global Warming Potential (GWP).

- It holds the highest possible BRE Green Guide rating of A+ and is manufactured with eco-friendly practices.

Value For Money:

- Kooltherm is long-lasting and durable, with its thermal efficiency not deteriorating over time.

- Due to its fine makeup, thinner Kingspan insulation can offer the same thermal efficiency as thicker fiberglass or mineral wool insulation, saving on material costs.

- It is lighter and easy to install.

Applications:

- Suitable for insulating various types of pipework, including mild steel, stainless steel, carbon steel, copper, multiplex, and plastic.

- Ideal for HVAC and building services applications in residential, commercial, or industrial settings.

In summary, Kingspan Pipe Insulation, particularly the Kooltherm Phenolic Pipe Insulation, is a top-tier insulation solution offering exceptional thermal performance, fire resistance, moisture resistance, and environmental sustainability. It is a cost-effective choice suitable for a wide range of pipe insulation applications.

Buy Kooltherm® Pipe Insulation

How to Use the Carbon Calculator Tool for Kingspan Kooltherm® Pipe Insulation?

To help you choose the appropriate thickness of Kingspan Kooltherm® Pipe Insulation for your project, Kingspan has developed a carbon calculator tool that can estimate the carbon emissions associated with the heat lost from pipework systems over their lifetime, when specified to tables in BS 5422: 2023, CIBSE CP1 or a specified insulation thickness. The tool can also compare the carbon emissions of Kingspan Kooltherm® Pipe Insulation with other insulation materials and show the potential carbon savings that can be achieved by using Kingspan Kooltherm® Pipe Insulation.

You can access the tool by visiting Kingspan’s website. The tool is easy to use and requires only a few inputs, such as the type of pipe, fluid, temperature, heat loss or condensation control objective, insulation material, and thickness. The tool will then calculate the carbon emissions per metre of pipework over its lifetime and display the results in a graph or table format. You can also export or print the results for your reference.

Frequently Asked Questions

Q: What is pipe insulation?

A: Pipe insulation refers to the process of wrapping pipes with a layer of material to prevent heat transfer and minimize energy loss.

Q: Why is pipe insulation important?

A: Pipe insulation is important because it helps in reducing heat loss, prevents condensation, and improves energy efficiency. It also protects pipes from freezing and minimizes the risk of fire.

Q: What is Kingspan Kooltherm pipe insulation?

A: Kingspan Kooltherm pipe insulation is a high-performance insulation material specifically designed for thermal insulation of pipes. It offers excellent thermal conductivity and has a low thickness for effective insulation.

Q: How does Kingspan Kooltherm pipe insulation work?

A: Kingspan Kooltherm pipe insulation works by providing a highly efficient barrier against heat transfer. The material used in the insulation has low thermal conductivity, which helps in reducing heat loss through the pipes.

Q: What is the insulation thickness required for pipe insulation?

A: The insulation thickness required for pipe insulation depends on various factors such as the pipe diameter, operating temperature, and insulation material used. It is recommended to consult the manufacturer's guidelines or industry standards like BS5422 for the specific insulation thickness requirements.

Q: Can Kingspan Kooltherm pipe insulation be used for hot water pipes?

A: Yes, Kingspan Kooltherm pipe insulation can be used for hot water pipes. It has excellent thermal properties that make it suitable for insulating both hot and cold water pipes.

Q: What are pipe supports and why are they important for pipe insulation?

A: Pipe supports are devices or structures used to hold and secure pipes in place. They are important for pipe insulation as they help maintain the integrity of the insulation by preventing any movement or displacement of the pipes.

Q: Does Kingspan Kooltherm pipe insulation have any carbon content?

A: Yes, Kingspan Kooltherm pipe insulation contains carbon as a component of the insulation material. However, it is important to note that the carbon content in the insulation material is minimal and does not pose any significant environmental or health concerns.

Q: Is there a calculator available to determine the carbon footprint of Kooltherm pipe insulation?

A: Yes, Kingspan provides a Kooltherm pipe insulation carbon calculator that allows users to estimate the carbon footprint associated with the use of Kooltherm pipe insulation. This tool helps in assessing the environmental impact of using the insulation material.

Q: What are insulated pipe support inserts?

A: Insulated pipe support inserts are specially designed inserts that are used to provide additional thermal insulation at pipe support points. They help reduce heat loss and prevent thermal bridging at these critical areas.

Buy Kooltherm® Pipe Insulation

Conclusion

Kingspan Kooltherm® Pipe Insulation is a high-performance pipe insulation product that can provide multiple benefits for your project. It can reduce heat loss or gain, prevent condensation, protect pipes from corrosion, enhance fire safety, and improve acoustic performance. It can also save space and cost, and reduce carbon emissions. By following the guidance of BS 5422: 2023 and using the carbon calculator tool provided by Kingspan, you can specify Kingspan Kooltherm® Pipe Insulation with confidence and achieve optimal results for your project.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *