- Blogs

- What is the difference between EPS and XPS insulation?

What is the difference between EPS and XPS insulation?

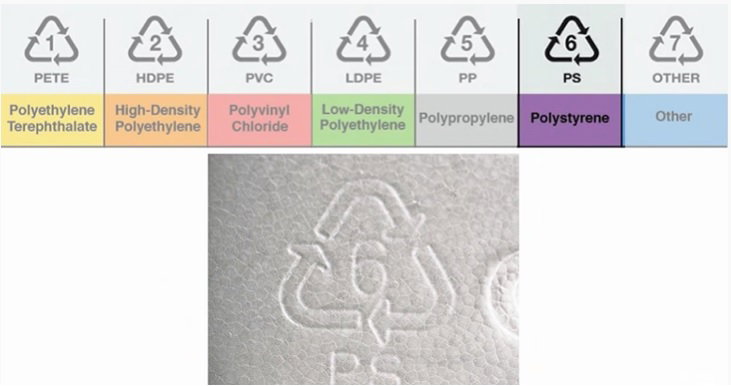

Polystyrene insulation has been the go-to choice for a variety of uses, not just as insulation but predominantly as packaging and single-use food and drinks containers.

It is used as floor insulation primarily along with being suitable for other applications like roof and wall insulation.

Polystyrene is used either in the expanded form (EPS) or the extruded form (XPS). Both of these foam insulation boards are known for their exceptional insulating properties.

In this blog, we will be discussing the main differences between EPS and XPS insulation. We will also cover EPS and XPS insulation individually, as well as polystyrene insulation, in general. We intend to highlight the difference between the two types of foam insulation boards, so that the next time you purchase insulation online or visit a DIY store, there will be no confusion.

Before we dive into the difference between the two variants of polystyrene insulation boards, let us first look into polystyrene insulation in general.

What is polystyrene?

Polystyrene is basically plastic that is created with styrene - a monomer. This hydrocarbon is versatile in application and is produced in tons every year. The monomer styrene is made of two petroleum products - benzene and ethylene. Under heat and pressure, the double ring of the ethylene breaks in the presence of oxidisers like benzoyl peroxide to produce a long-chain polymer called polystyrene.

What makes polystyrene a good insulator?

Polystyrene is a colourless, transparent thermoplastic that is often used in the manufacture of polystyrene beads and foam insulation boards. Small polystyrene beads can also be used as cavity wall insulation, where they are poured in loose to fill the cavity.

beads and foam insulation boards. Small polystyrene beads can also be used as cavity wall insulation, where they are poured in loose to fill the cavity.

Polystyrene insulation is also commonly used to insulate concrete forms and structural insulated panels or SIP construction systems. About 95-98 per cent of polystyrene insulation contains air. Millions of tiny air pockets resist heat transfer through the fabric of the material. It is this very property that makes polystyrene a good insulator.

Both EPS and XPS are made of polystyrene it's just the way they are produced that differentiates them. The way these foam insulation boards are made affects their thermal conductivity and the way they react to moisture. Let us look into them individually before we point out the differences.

What is EPS insulation?

EPS is a thermoplastic and typically comes as a rigid foam insulation board or loose beads.

EPS insulation boards contain thousands of tiny air bubbles which means that EPS foam insulation boards contain 98% air and only 2% plastic. This is what makes it super light to carry, handle and easy to install. EPS insulation boards are available in white and grey colours.

How is expanded polystyrene made?

The liquid polystyrene is dropped in water, under the right conditions, to form small beads. The polystyrene expand in the presence of blowing agents and heat. These are moulded into large blocks or sheets in the presence of steam. The large blocks are then cut into thinner lightweight sheets or required shapes using hot wire machines.

What is EPS insulation used for?

Certain EPS insulation boards are cost-effective and ideal for floor and underfloor insulation. Only flooring grade EPS should be used, not just any type as not all EPS is created equal! Some have higher density and compressive strength than others, allowing them to be used underfloor and carry the weight of screed, people and everyday objects. The insulation boards must be installed on level ground. Flooring grade EPS are pressure-resistant, so they help prevent the floor from cracking or collapsing.

Certain EPS insulation boards are cost-effective and ideal for floor and underfloor insulation. Only flooring grade EPS should be used, not just any type as not all EPS is created equal! Some have higher density and compressive strength than others, allowing them to be used underfloor and carry the weight of screed, people and everyday objects. The insulation boards must be installed on level ground. Flooring grade EPS are pressure-resistant, so they help prevent the floor from cracking or collapsing.

EPS insulation is very versatile in application and can be used in wall and roof insulation in residential buildings.

At Buy Insulation Online, we store EPS insulation from top brands like Kay-Metzeler and Jablite. Both are well known for their high compressive strength and insulating properties.

What are the advantages of EPS insulation?

1. The R-Value or the insulating capacity of the EPS insulation is not lost over time unlike other insulation materials like fibreglass.

2. EPS provides excellent value for money, is versatile, and will last for decades.

3. The foam insulation boards have a very high level of insulation value and help achieve the required U-values necessary to meet building regulations.

4 . It contains many tiny air bubbles in its fabric, and since air is not a good conductor of heat, it provides excellent insulation.

5. It does not use any CFCs or HCFCs that harm the environment. At Buy Insulation Online, we store EPS insulation that is rated A+ by the BRE Green Guide Specification. EPS has no ozone depletion potential and is commonly recycled in industry although it must be said, not easy for the general public to recycle.

6. EPS is non-toxic, non-irritant, and chemically inert, making it hygienic and safe. It is inhospitable to fungi, moulds and bacteria.

7. The polystyrene cellular matrix which is made of 2% polystyrene, provides excellent impact resistance. It is the reason why the EPS insulation has high compressive strength considering the fact that it is 98% air!

Disadvantages of EPS insulation:

1. The manufacturing process makes use of Hexabromocyclodecane, which is a toxic chemical.

2. EPS insulation is not-resistant to ants and termites.

3. It is non-biodegradable and will take 100’s of years to break down in the environment.

4. EPS insulation is flammable and releases dangerous toxic smoke when lit. It is hence not used in applications requiring fire resistance.

5. EPS is not easy for consumers to recycle, due to the fact that local authorities don't have the facilities to handle it. This leads to huge amounts ending up in landfills and escaping into nature where it breaks down into the tiniest of beads which do not degrade and pollute the environment. Therefore it should be disposed of carefully, not allowing it to break up and try to only order as much as you need to insulate the area in question.

What is XPS insulation?

Extruded Polystyrene (XPS) is a high-performing, rigid foam insulation board. The closed-cell structure of the foam insulation boards keeps moisture out. The XPS insulation board comes in many grades for applications wherein resistance to heavy loads and extreme moisture is required. In theory, it is stronger and has better mechanical properties than EPS. It is also more expensive compared to EPS.

How is XPS insulation made?

As mentioned earlier, the EPS and XPS insulation are made of the same material - polystyrene. But instead of forming tiny beads that are then foamed, XPS is manufactured through the extrusion process.

Liquid polystyrene is first mixed with blowing agents and additives and then extruded through a dye. The mixture then expands on cooling, resulting in tightly packed, closed-cell insulation called XPS.

What is XPS insulation used for?

XPS insulation boards are perfect for insulating beneath concrete slabs and for other underfloor insulation applications. They can be used to insulate cavity walls, roofs, external walls and so on. XPS is also an excellent foundation wall insulating material.

Why use XPS insulation?

1. The XPS insulation provides exceptional moisture resistance, which makes it an ideal insulating material  for inverted roof applications. This tightly packed, closed-cell insulation is least affected by moisture.

for inverted roof applications. This tightly packed, closed-cell insulation is least affected by moisture.

2. The R-value of the foam insulation board does not dissipate or reduce with time.

3. It contains only a 2% cellular matrix like the EPS. The closed-cell insulation is well-known for its exceptional compressive strength.

4. Much like the EPS, the XPS insulation is versatile and will last for a lifetime.

5. The XPS foam insulation boards also help achieve the required U-values necessary to meet building regulations.

6. The XPS insulation board does not use any CFCs or HCFCs that harm the environment. It has no ozone depletion potential or global warming potential. XPS insulation is also 100 per cent recyclable, which makes it an environmentally-friendly choice.

7. XPS insulation does not support or promote the growth of bacteria, moulds or fungi. It is lightweight and easy to install and does not harm the skin.

The XPS insulation that we store at Buy Insulation Online is from Polyfoam XPS. The product is certified ‘A’ by Green Guide and has a thermal conductivity of 0.033W/mK, making it a very effective insulator.

Disadvantages of XPS insulation:

Much like the EPS, the XPS insulation degrades under direct sunlight and is flammable. It is not resistant to ants and termites. It also contains toxic hexabromocyclododecane and is non-biodegradable.

What are the differences between eps and xps insulation:

As mentioned earlier, even though both the EPS and XPS insulation are made of the same polystyrene, the way it is made of manufactured changes it physical and chemical properties. Let us have a look:

Compressive strength:

Since the cells in the XPS insulation are bound closely together, they exhibit higher compressive strength. The increased cell density is why XPS insulation boards are used in most load-bearing applications.

That's not to say that EPS cannot be used in load-bearing situations. As mentioned earlier, flooring grade EPS can be used but it is a fact that XPS is much better in this regard, allowing thinner thicknesses to be used and therefore the floor will not have to be dug out so much or it won't affect ceiling height.

If one has to achieve the same compressive strengths as XPS using EPS, the density of the EPS foam boards would have to be much higher. The whole process of manufacturing such foam boards would be elaborate and time-consuming making the end product a lot more expensive and not financially viable. It would also increase the thickness of the EPS board, which may not be suitable for the job at hand.

One application where the lower compressive strength of EPS comes in handy is the use in foundations to protect against clay heave. This is where clay soil can expand and contract, causing pressure or ‘heave’ on the foundations which can cause cracking and subsidence. EPS can act kinda like a suspension on a car, contracting when the soil pushes against it and expanding when the soil contracts, thus protecting the foundations from subsidence.

Water-resistance:

The difference in water resistance comes down to the fact that XPS has a fully closed cell structure, rather than the partially closed cell of EPS.

Closed-cell insulation means that there are no gaps between the air bubbles, preventing water ingress and permeation.

EPS has a water vapour diffusion resistance of 30-70, whereas XPS has a water vapour diffusion resistance of 80-250. XPS is less permeable to air and moisture than EPS. So, if you need to insulate areas that have high moisture content, XPS insulation is the way to go.

When EPS insulation boards are exposed to moisture, water can accumulate in the spaces between beads. Water affects the R-values of the EPS and the effectiveness of the insulation decreases. Also, under freezing conditions, the water present in between the beads can freeze and expand. When this water expands, it breaks the connection between the beads, thus lowering the insulating efficiency even further.

Since in XPS, the cells are tightly packed together, water cannot get into its fabric. So they are better at resisting moisture than EPS insulation. They are hence more tolerant of wet conditions.

Thermal conductivity:

The air inside the fabric of the EPS conducts heat easily. This is why the thermal conductivity of XPS begins at a lower level than that of EPS. To achieve the same conductivity as that of XPS, a higher density or thickness of EPS insulation would be required. Making high-density EPS insulation boards would reduce the voids or gaps between the polystyrene beads, increasing cell density.

In short, XPS insulation has a slightly lower thermal conductivity than EPS. It means XPS will allow heat from passing through its fabric at a slower rate when compared to EPS insulation.

In conclusion:

XPS usually beats EPS in every department, except for cost where there is a large difference. This causes them to be out of budget for a lot of people. That means EPS is usually the most cost-effective, budget-friendly choice.

Having said that, XPS is more durable and efficient in the long run. Their performance is consistent, and they are least affected by moisture compared to EPS boards. When compared to EPS foam insulation boards, XPS is obviously an upgrade, so if it suits your application and budget, go for it.

If you are still unsure about what to use, please contact us by email or phone and we will guide you through the process of choosing the right insulation board for you.

For top-quality insulation boards and other building supplies like loft insulation, pipe, duct insulation or valve jackets, visit Buy Insulation Online.

We also plant three trees per order. By purchasing insulation online from us, you become carbon-positive and your building becomes more energy-efficient

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *