- Blogs

- Cold Weather Solutions: The Benefits and Applications of Trace Heating

Cold Weather Solutions: The Benefits and Applications of Trace Heating

Trace Heating is a term used to describe, basically electric cables which when an electrical current is passed through them, warm up to a preset temperature. They are installed directly onto pipes and valves etc to prevent freezing and maintain temperatures.

Trace Heating, in addition to pipe insulation, prevents pipework, tanks, and vessels in your facility from freezing over and causing serious damage. Trace heating also maintains the temperature of the water in the hot water pipework, to help prevent Legionnaires disease from forming within.

In this blog, we will be discussing all about trace heating. We attempt to answer some of the important questions relating to this topic.

While you don't have to be a trained electrician to install trace heating, however you do need training so you are competent to do so and you should never attempt to install without training nor attempt to connect the trace heating to the mains power, only qualified electricians can do this

If you are interested in the training, please contact us and we can put you in contact with a partner of ours who will provide the training free of charge for you.

Buy Insulation Online, store and supply an array of trace heating kits and supplies, at the most competitive prices from a world class manufacturer.

Trace heating: what is it?

Simply put, trace heating is an application in which heat is applied to pipes, vessels and valves through special cables or heating wires, to prevent them from freezing. There are small wires inside the cables which heat up when an electrical current is passed through them, in the same way an electrical heating element works.

Trace heating also maintains the temperature of the fluids in these systems at optimum levels. Trace heating cables are placed in direct contact with the pipes along the length of the pipe until the pipe reaches a fixture or terminates.

Pipe insulation along with cladding is often put over the heating cables for 2 reasons

- Trace heating alone would not be enough to prevent freezing / temperature drops so pipe insulation is required at the correct thickness to be the first line of defence against freezing, with the trace heating there to support if there is a steep drop in temperatures.

- Trace heating has the potential to electrocute someone if they cut or damage the insulation without knowing there's an electric cable beneath. Therefore, cladding the pipe will help prevent this from happening along with placing warning stickers all along the outside of the pipe insulation to inform people that there is a live electrical cable beneath.

Pipe Lagging prevents the heat generated by the heat trace cable from dissipating into the environment. The heat is supplied using thermostats which are hooked up to the mains power, which then supplies the cable with just the right amount of Amps to sustain or achieve a target temperature of the pipe, which is set on the thermostat itself manually or through the Building Management System or BMS.

Is trace heating important?

Pipes and valves situated outdoors are more susceptible to freezing as the temperatures drop when compared to those within the building.

drop when compared to those within the building.

If the temperature of the liquids moving within these pipes is not maintained, the pipes would freeze. Freezing expands the water within the pipes leading to pressure build-up. The extreme pressure can trigger cracks within the pipework, ultimately breaking them.

Burst pipes are an extremely messy affair, especially if they are not caught early. They can flood entire premises, destroy property and fixtures and cause the building to be uninhabitable whilst the repairs are taking place.

Trace heating is a cost effective insurance to an otherwise potentially expensive and disruptive problem.

What is trace heating used for?

Trace Heating is a low-cost solution for freeze related and temperature maintenance issues. Heat tracing is applied predominantly on commercial and industrial facilities, including hospitals, office buildings, schools etc

Trace Heating can help conserve energy and make the building energy-efficient through the following applications:

Maintains water temperature:

Trace Heating helps maintain the temperature of the circulating warm water, thereby conserving energy and avoiding heat loss. It eliminates the requirement to re-heat water.

Freeze protection:

As discussed earlier, pipe situated outdoors are highly susceptible to freezing, which could lead to ruptures and other issues. Trace heating cables, warm the pipes and prevent the fluid from freezing over, in turn preventing bursts and structural damage.

Preventing fire fighting sprinkler systems from freezing:

This is an application which can literally save lives and property. If the sprinkler system freezes then the whole building could burn down, potentially killing people and ruining lives. Trace heating is crucial in this regard to prevent this from happening.

Preventing legionnaires forming in hot water pipes:

Legionella bacterias are frequently found in water. The bacteria increase where temperature levels are in between 20-45°C and nutrients are readily available. The bacteria are inactive below 20°C and cannot withstand temperatures above 60°C.

It is possible to contract Legionnaire's disease from residential domestic water pipes, but this is extremely uncommon. The majority of breakouts happen in big complexes, such as hotels, health centres, museums and offices due to bigger, more complicated water system systems where germs can rapidly spread.

By maintaining the temperature in the pipes above 55°C, trace heating prevents legionella bacteria from being able to survive and thrive, therefore ensuring the safety of the occupants of the building.

Trace heating is extremely flexible in its applications:

Trace heating finds applications in many industries like the oil and beverage industry, gas, food, transport, pharmaceutical, water treatment centres among others. In industries, trace heating is mainly used for freeze protection and temperature upkeep, among many other things.

What are the components of a trace heating circuit?

A typical trace heat system consists of the following elements:

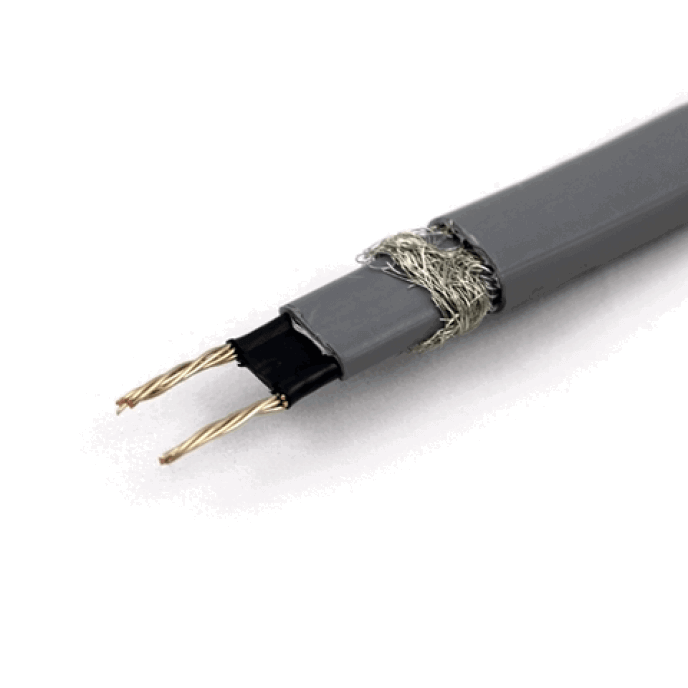

The Heating Cables: The trace heating cables are connected to the surface area of the pipes, valves or tanks. They are secured in place using cable ties or heat-resistant tapes.

The Heating Cables: The trace heating cables are connected to the surface area of the pipes, valves or tanks. They are secured in place using cable ties or heat-resistant tapes.

Power Connection Kits: The heat tracing cables is linked to the source of power, through a power connection box. If the set-up is larger and requires higher control and precision, a digital thermostat is used.

Digital Thermostats: Trace Heating thermostats help to keep track and control the temperature running through the system. They also accommodate power connections if your system is large and requires higher control over temperature level. A thermostat manages the amount of thermal energy produced via trace heating cables, making sure that the cables do not overheat or underheat.

Connect-a-box or Connect-a-tube: Connection boxes are used when there are junctions (T-shaped joints or 90-degree bends) along the pipeline that should be warmed. These connection boxes come with 2- way or 3- way entry points that can accommodate multiple entries needed to divide the heating cable run.

End-Termination Kits: End termination kits are used wherever there is an end in the pipeline and heating cables need to be terminated. Terminating and neutralising the cable run with end kits helps to improve workplace safety. End-termination kits help determine any fluctuations in the power supplied. Tracing these fluctuations will be much easier if a signal lamp/indicator is added to the end-seal.

The pipe insulation completely covers the trace heating installed to offer total security and to stop heat loss. By putting electrical trace heating labels, every 1m or so, creates awareness of the electrical cable within the insulation which will help prevent the cable being cut or damaged inadvertently, which could potentially kill someone.

How does trace heating prevent legionnaires disease?

Legionella germs are typically discovered in hot water pipes which feed your taps and showers at home along with in industrial/commercial settings like hot tubs and spas.

It's especially dangerous for the elderly, smokers and those with existing health conditions such as chronic respiratory issues.

A study in 1991 was conducted and found that trace heating was effective at killing bacteria within the pipe if it is installed correctly and with pipe insulation -

“A self-regulating trace heating element was assessed for its ability to maintain a temperature of 50 degrees C in the mixer valve and dead-legs of a shower, and for its effect on legionellas colonizing the shower. The trace heating element maintained a temperature of 50 degrees C +/- 1.5 degrees C in dead-legs when the circulating hot water supply remained above 45 degrees C. Legionellas appeared in a trace heated dead-leg when the temperature of the dead-leg reached 45 degrees C and the hot water supply dropped below this temperature. Legionellas were eradicated or significantly reduced in sections of the shower where a temperature of 50 degrees C was consistently achieved. The mixer valve which was trace heated but not insulated remained colonized with Legionellas. Legionellas were found in shower water throughout the study”

Self-regulating trace heating cable is able to change its power output to make up for variations in water and ambient temperature levels. Therefore the water within the pipe can be maintained above 55 degrees celcius even if there is an issue with the hot water tank and system for example, which will prevent the legionella bacteria from being able to form and reproduce.

What are the different types of heating cables?

Heating cables are of two different types: consistent wattage and self-regulating (likewise called self-limiting).

Constant Wattage Heating Cables: These trace heating cables use two normal copper conductor wires (neutral and live). The conducting material produces uniform heating power (Watts/m) over the entire length of the cable.

Self-regulating heating cables: They differ from the constant wattage cables, both in make-up and performance. Often called Heat trace cables or Heating cables, they regulate temperature, by automatically adjusting power output based on the surrounding temperature.

The self-regulating heating cables respond to variations in temperature levels at each point along the length.

They also minimise hotspots and prevent overheating by providing exactly the right amount of heat when and where it is needed.

We store two kinds of self-regulating heating cables here at Buy Insulation Online:

Self-regulating heating cables for freeze protection: Supplied in lengths varying from 1m to 200m, the heating cable assists in frost security of water pipelines. They are appropriate for all kinds of pipes including composite metal pipelines, copper, stainless-steel pipelines, plastic pipes and threaded pipes. The power output of these cables varies from 10w/m to 30w/m with a power wattage of 200 - 277 Vac.

the heating cable assists in frost security of water pipelines. They are appropriate for all kinds of pipes including composite metal pipelines, copper, stainless-steel pipelines, plastic pipes and threaded pipes. The power output of these cables varies from 10w/m to 30w/m with a power wattage of 200 - 277 Vac.

Self-regulating heating cable for Hot-water Maintenance: The Self-regulating cables from Buy Insulation online successfully maintain the temperature of hot water in pipelines. It is particularly beneficial in industrial applications where even a small loss of heat can trigger viscosity and circulation issues. It can also be utilised for warm water pipelines in commercial and residential settings.

Provided in lengths varying from 1m to 150m, the self-regulating heating cables have an output voltage of 9 or 9.5 W/m.

How does trace heating work?

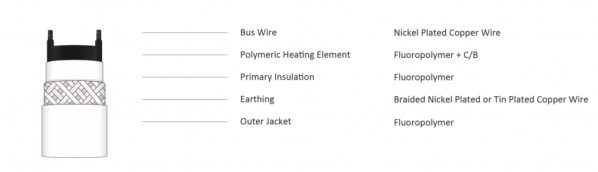

Trace heating cables are more complex compared to standard heating wires. Two bus wires, one live, another neutral, are wrapped in a semi-conductive and self-regulating Polymetric heating element, to make the trace heating cables.

The Polymetric heating element is heated up when the electricity of either 230V or 110V runs through the bus lines. There are different types of heating element which all have specific chemicals that change their resistance depending on its temperature at different points along the line.

If the temperature gets too hot in a particular spot on the pipe run, the cable is able to cool down, even if the rest of the pipeline is at normal temperature. This implies that the cables can cross without the risk of being overheated.

Where should the trace heating cable be positioned?

There are various locations where the heating cable can be put on the pipeline surface area. Preferably, the trace heating cables need to be put at 4 'o'clock and 8 'o'clock positions on the lower quadrant or part of the pipe. It is an ideal position for the heat tracing cable.

You can also place the heating cables at 10 o'clock and 2 o'clock positions if space constraint exists.

Spirally wrapping the heating cable around the pipe is not recommended. In short, spirally wrapping the heating cable is expensive as it requires more labour and materials and does not provide the required results.

How to setup a trace heating system?

Trace heating installation needs to be performed by an accredited and certified person.

Trace heating installation needs to be performed by an accredited and certified person.

Identify the correct trace heating system by calculating heat loss, class, length, maximum operating and ambient temperatures. If you need the calculations done for you we can help with this so please contact us and enquire about this service.

Ensure that the pipes are in perfect working order, do a pressure test, if required.

Determine the path of the heating cables by checking the length of the pipes. Ensure the pipe surface area, where the heat-resistant or glass-fibre tapes would be placed is without any rust, dirt or any other blocking items. Place the trace heating cables at the 4 and 8 'o'clock positions. Thermostats or any heat-sensing device must be placed at 90-degrees from all heating cables.

Even though the trace heating cables regulate their power output, all trace heating applications must be temperature controlled using a suitable thermostat. Integrate the trace heating cables with termination and splice packages, tee packages, end seals, and other accessories to finish the trace heating unit.

In conclusion:

Trace heating has been used in different forms for over 100 years and is still the most effective freeze prevention and temperature maintenance solution available on the market today.

They are an energy-efficient solution for ice and snow melting. Since the heating cable just focuses output on the part of the pipeline or vessel where it is most needed, it ensures that energy is not lost or wasted. When used in conjunction with appropriate pipe insulation, the energy use can be kept to a bare minimum.

For the best quality trace heating solutions you can get on the market today such as complete trace heating kits, visit our Trace heating page here.

We provide pipe lagging, ductwrap and duct board insulation, valve jackets and other general insulation at highly competitive prices.

We also plant three trees per order, offsetting your carbon and helping to reforest the Earth and stop deforestation. Together we can make a difference, so feel good about your insulation purchase with us.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *