- Blogs

- Why pipe insulation in your loft and other cold spaces is a must.

Why pipe insulation in your loft and other cold spaces is a must.

Lagging pipes in loft spaces has multiple benefits and in fact, there can be substantial risks by not insulating pipes in unheated areas of your property.

With the way soaring energy prices are eating into our disposable incomes, we need to find as many ways to reduce our energy consumption as much as possible.

Insulating your pipework, especially in cold spaces, should be a priority when assessing where to start with insulating your property alongside installing more loft insulation. These are two easy wins for homeowners to reduce their energy bills effectively and without breaking the bank.

Insulating your loft and your pipe work should only take one weekend complete on an average-sized home, and once it's done you can sit back and enjoy the savings and increased comfort that insulation brings.

If you're looking for advice on pipe insulation, including how to insulate water pipes properly, this comprehensive guide will tell you why you should start insulating pipes that run not just in your loft space, but throughout your property.

Some quick context

Please be aware that we have written this guide predominantly with homeowners in mind but the points made work equally well in commercial properties such as office buildings, shops, gyms and spas, business premises such as hairdressers, for example, the list can go on and on.

Also whilst the subject of the article is why pipes need lagging in the attic space, you can substitute the term loft/attic with garage, shed, underfloors, cellars, basements or any other cold space you can think of and the advice is still appropriate and on point.

All of the advice given here holds just as well in a hot country too. Except, a lot of the reasons are reversed from preventing heat loss, to preventing heat gain instead and you will see that cold pipes on air conditioning units for example need insulating just as much as hot water

This guide is also quite long so feel free to skip any bits you already know or are not relevant to your situation.

Why do you need to insulate water pipes?

There are many reasons why we recommend you should be insulating your pipework in your loft space and also any other cold space within your house, such as garages, cellars, under-suspended floors in older buildings, and also external outbuildings.

Here are the top 10 reasons why its wise to insulate your pipes

- Pipe lagging prevents burst plumbing

- Prevents heat loss, heat gain and increased internal comfort

- Lagging Pipes Lowers Energy Costs

- Lowers your carbon footprint

- Pipe insulation can protect pipes from corrosion and damage

- Protects immediate surroundings around pipework

- Prevents legionnaires disease

- Reduces workload on your boiler or HVAC equipment

- Can acoustically insulate pipes

- Can provide resistance against fire

Let's go through these reasons one by one.

1. Pipe Insulation prevents frozen pipes

The main reason to insulate water supply pipes exposed in your loft is that pipework in these areas is susceptible to frost.

Therefore, if temperatures reach 0 degrees celsius in these areas and cool the plumbing to a point where it freezes, which is especially true for cold pipes which are already going to be very cold at this time of year, then the frozen water within the pipework will expand.

In cold climates, the inside of a pipe can freeze and thaw many times over the course of the year. This will stress the copper or plastic material that the pipe is made out of to the point where it cannot hold the expanded water anymore and as a result, cause the pipes to burst.

Once the pipe has thawed, water will then continue to flow through the rupture. Now, this is obviously going to cause a huge problem because the water will come gushing through your ceiling spaces into your living spaces.

This could happen and you could be asleep in the middle of the night, you could be away on holiday or out of the house for a day or two, and then when you come back, you find that your house is flooded because the mains cold water pipe work as nonstop pumped cold water through the ruptured pipe into your loft space and throughout the entire house.

Damages could run into 10s of thousands of £'s. You may also have a fight on your hands with getting paid out by insurance as we all know how difficult insurance companies make it to claim successfully, not to mention all the time spent on cleaning up and the possibility of having to stay in a hotel or relatives until the house is habitable again.

And it doesn't have to be a major leak that causes a torrent of water that can cause a lot of damage either. The weakest point of any pipework system is on the fittings such as an elbow or a tee piece. Frost might not burst the pipe enough to constantly gush water but instead cause the fitting to weep a small amount.

At first, it won't be apparent but given enough time the leak will soak the area around it and eventually show itself in the form of a damp patch on the wall or ceiling.

You will then have a major problem on your hands because it will take time for you to identify the source of the leak because it could be hidden under layers of loft insulation or other items put in storage. It could also be travelling from the source of the leak, along joists, etc and finally, end up nowhere near the damaged pipe.

Even when the leak has been fixed, the damp area could take months to dry out properly and if it isn't taken care of quickly then mould will take hold which can be a nightmare to get rid of once it establishes itself

2. Insulating Pipes Improves Comfort by reducing heat loss

In addition to the problems that can be caused by frozen pipes bursting, another issue that can occur is that hot water pipes also lose heat.

In addition to the problems that can be caused by frozen pipes bursting, another issue that can occur is that hot water pipes also lose heat.

This is because a lot of heat is lost through the surface area of a pipe. Not only will this cause you to waste energy and make your energy bills higher (we'll talk about this in a moment) but it will mean that your radiators will take longer to heat up and quicker to cool down alongside your hot water pipes which feed showers and taps.

This impacts your comfort because you have to wait for radiators and showers to get up to desired temperatures longer, which is felt especially in winter.

This is because a lot of heat is lost through the surface area of a pipe. The goal of pipe insulation is to stop this flow of energy, in the form of heat, keeping more of it in the pipe for longer.

3. Pipe Insulation Lowers Energy Costs

When you have properly insulated pipework, you will be reducing the amount of heat that is lost through the surface area of the pipe – meaning that your radiators will need to work less hard to keep your home at a comfortable temperature.

As we mentioned earlier, this can mean that you will have to spend less on your energy bills each month.

One of the main reasons to use pipe insulation is to eliminate this heat loss or at least reduce its impact to where it's not felt as pronounced.

4. Lagging Pipes Lowers your carbon footprint

Properly insulated pipes as discussed already means you will need less energy to condition, either heat or cool, the contents of the pipe either for heating or cooling air conditioning.

This means that you will in turn indirectly emit less carbon, therefore lowering your carbon footprint. This is better for the planet and over the course of its lifetime insulation is one material that will prevent more carbon from being emitted that was caused during its manufacture, which is not the case for most building materials.

5. Pipe Insulation can protect pipes from corrosion and damage

Pipe insulation is an important part of any building's plumbing system. It can protect pipes from corrosion and damage, which can be costly to repair or replace. It also prevents condensation to form on the pipes, which can cause rusting and corrosion.

Most pipe insulation is relatively robust in the sense that it can sustain a bit of damage which can cushion a blow that would have otherwise been a direct hit that could have caused the pipes to burst on impact.

Having said that though you should be using pipe insulation cladding like aluminium or PVC Isogenopak along the pipes in exposed areas such as externally or which are liable to be damaged.

6. Insulating pipes can prevent damage to their surroundings

You might be wondering what could we mean by this.

Well, using pipe insulation that comes with an inherent vapour barrier built into it, that is, it has a jacketing such as a foil facing that prevents moisture from perforating through it, can prevent hot and cold pipes from sweating due to condensation forming on the surface of them.

Condensation on pipes can have a range of damaging effects, such as corrosion, microbial and mould growth, and also structural damage.

That's why insulating copper pipes, in particular, exposed cold pipes is a great way to eliminate pipe sweating and humidity problems.

Corrosion of metal pipes is caused by the existence of moisture, as well as this can result in leakages as well as various other problems.

Furthermore, condensation can offer a perfect environment for microbial growth, which can, even more, bring about health issues as well as contamination of the water if there is a slight fissure in the pipe allowing it to enter.

Finally, condensation can lead to structural damage, as the condensation can mean water dripping off the pipes, onto nearby surfaces. When the weight of the water-soaked surface means its integrity is compromised, it can fail, leading to things like ceilings falling through.

Taking action to prevent condensation on pipes is necessary for the security as well as durability of any type of plumbing system.

7. Properly Insulated Pipes can help prevent Legionnaires disease.

We go into this in more detail on a blog specifically written for this subject which you can find here.

However, just to summarise, by insulating your hot water pipes you can maintain the hot water temperature at a level which prevents Legionnaires bacteria from existing and multiplying within the pipework.

8. Insulating Pipes Can Extend the Life of Your Heating System

Another benefit of properly insulating your pipes is that it can extend the life of your heating system.

This is because if there is less heat loss through the surface area of the pipes from your boiler, then less energy will be needed to heat up the house. The benefit of this is that the temperature setting on your water boiler / heater can be set lower. Your boiler will thank you for it over the long run.

This in turn means that your heating system will work for longer before needing to be replaced or repairs need doing.

9. Insulating Pipes Helps Reduce Noise

Insulating pipes not only helps reduce heat loss but also reduces noises and vibrations.

Unwanted noises can happen because the water is constantly moving within the pipe and this can cause vibrations that travel through the structure of the building. They can also occur when air gets trapped in pipework, causing loud creaking noises.

If the plumbing is not installed correctly, then in gaps where pipes penetrate through walls, they could cause noise by vibrating and rattling.

Therefore acoustically insulating pipes with either Rockwool Pipe Insulation or Isover Pipe Insulation can effectively dampen noises emanating from pipework. Nitrile rubber like Armaflex, the black flexible pipe lagging you have probably seen around, works pretty well too.

There is also specialist acoustic pipe insulation such as the ones that can be found here. It is usually made of dense foam or rubber which has mineral wool adhered or stitched to it, making an effective barrier against sound.

It must be said that it's usually only used on soil and drainage pipes though in most real-world use cases.

10. Some types of pipe insulation can help resist fire

In order to ensure the safety of buildings, many types of pipe insulation can be used to help resist fire. Most modern pipe insulation is what's called Class 0 Rated in the UK, which basically means they are designed to resist the spread of fire along their surface.

However there is specially designed Fire-rated pipe insulation which is designed to provide protection from fire and smoke and can be used on water lines, gas lines, and drains.

It is important to choose the right type of insulation for each application to ensure maximum protection for buildings.

Additionally, it is recommended that all insulation be installed by a professional to ensure proper installation and protection, as it may be the pipe needs to be covered in a fire retardant before you put the insulation around the pipe.

If you are unsure you can contact us and we will advise you as best we can or alternatively a TICA-affiliated thermal insulation contractor.

What about insulating pipes in cellars and under suspended floors?

Cellars and underfloor suspended floors are probably more sheltered from freezing temperatures considering they are actually below ground or surrounded by brick walls rather than just thin roof tiles.

However, you still need to insulate them to prevent heat loss in heating and hot water pipes, and as insurance against cold water pipes freezing.

Now we have dealt with why you should insulate pipes in the attic and elsewhere, let's look at what to look for when choosing pipe lagging.

How to choose the right pipe wrap insulation

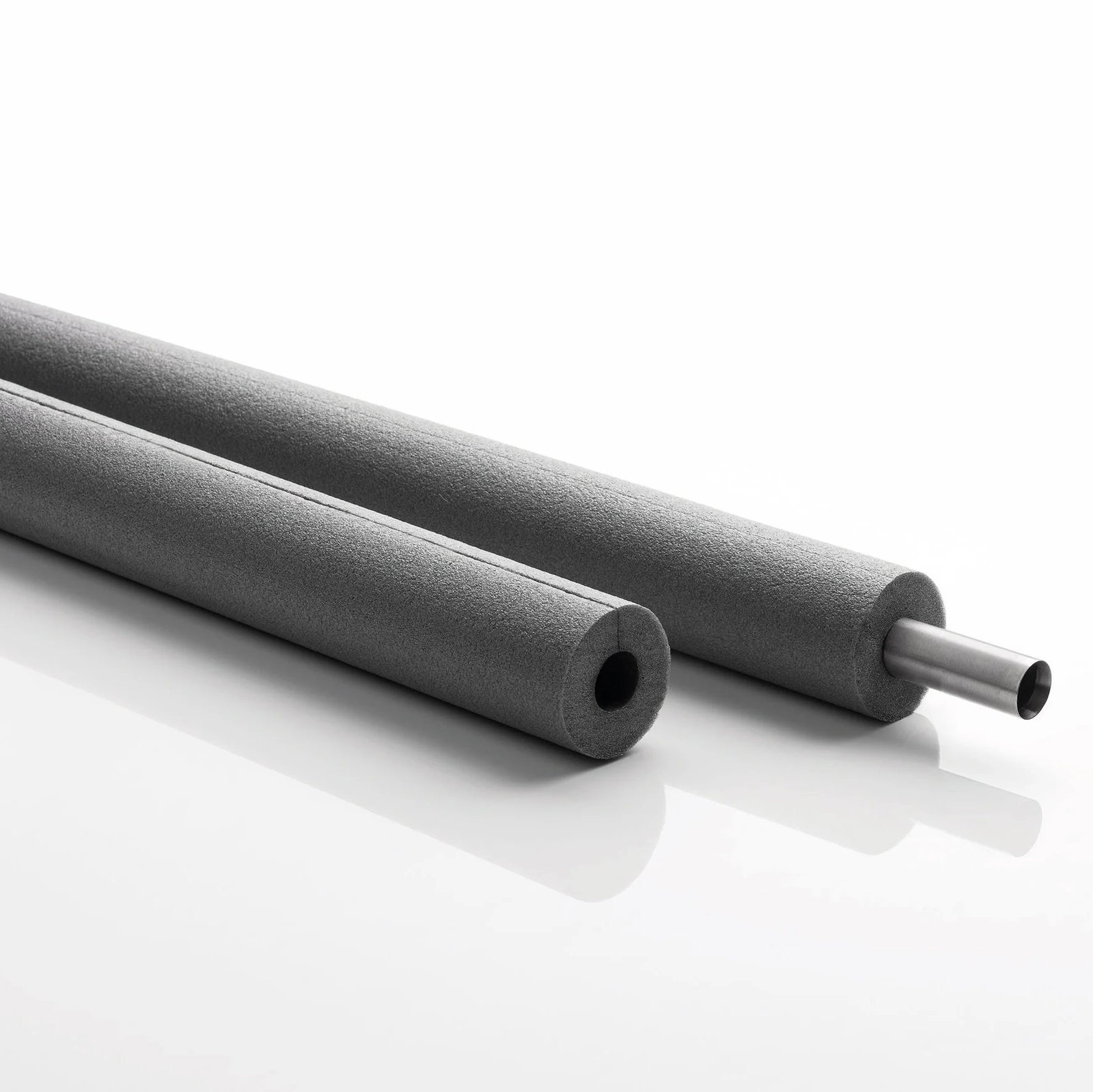

Pipe lagging is determined based on three factors: wall thickness, length, and bore size.

Wall Insulation thickness

How thick should the wall thickness be? That's one of the most asked questions surrounding pipe insulation. For example, if your pipe lagging is said to be 25mm thick, it means it has 25mm of insulation on both sides.

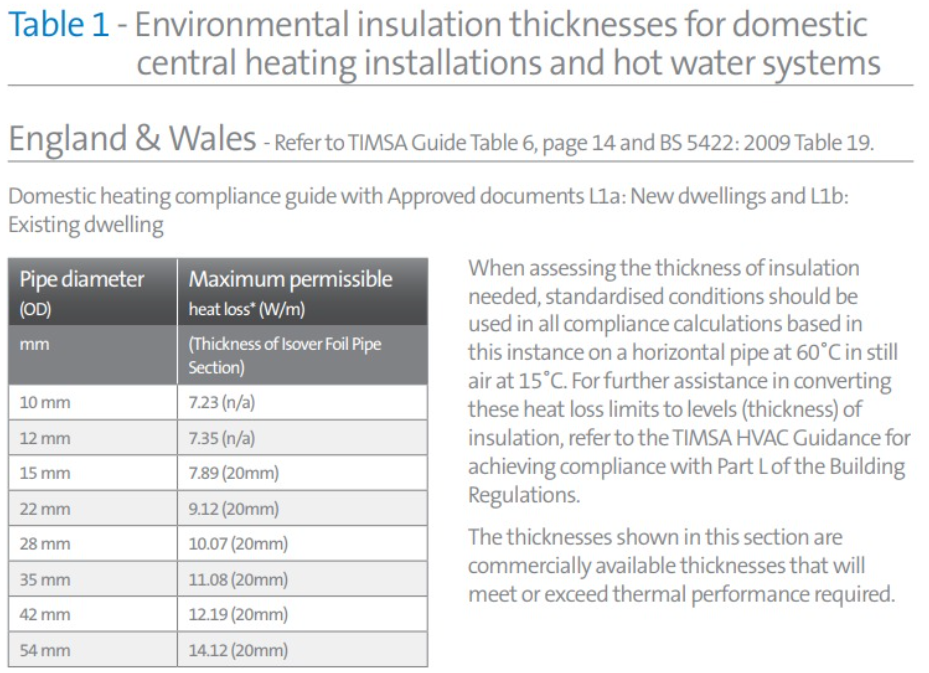

Strictly speaking, water pipe insulation needs should be as thick as British Standard 5422:2009 dictates. You can find these thicknesses on the data sheets that the pipe insulation manufacturers make to accompany their products.

We will do another article on this another day but we have taken a screenshot from the Isover Fibreglass Insulation guide for both Domestic Heating thicknesses and for Non-domestic. You will note that non-domestic requires thicker pipe insulation.

Choosing the correct pipe insulation largely depends on the wall thickness. The insulation must be thick enough to give you the results you are looking for, but too thick insulation may be impossible to fit because the brackets that the pipes hang off may not permit more than say 10mm, especially if the white plastic clips are used as shown in the picture.

If you don't have much space to wrap the insulation around because pipes are installed too close to the wall, for example, it's best to choose a 13mm or 9mm thick nitrile rubber pipe insulation.

This is because you will not be able to fit 20mm thick glasswool pipe lagging for instance and you should insulate the pipes with the maximum permissible thickness, even if it's only 9mm wherever you have access.

Something is better than nothing!

If space is not a constraint, then 20mm thick pipe insulation, or more if you can, would be the best option to maximise efficiency using most types of pipe insulation materials.

A simple rule of thumb is that the bigger the heating or hot water pipe, the thicker the insulation because it has more surface area and thus loses heat faster.

For frost protection, however, the equation is reversed. The smaller the pipe, the thicker the insulation you need because a smaller volume of water freezes more quickly.

Therefore, when the goal is to prevent frozen pipes you should check the manufacturer's thicknesses as per BS5422:2009

Bore size

Bore size refers to the diameter of the hole which runs down through the length of the pipe wrap insulation. It is determined by the pipes you're looking to insulate. For example, a 15mm copper pipe requires pipe insulation 15mm bore size.

The pipe diameter is measured across the pipe from side to side, in inches or millimetres although millimetres are more often used these days.

Please be aware that steel pipe sizes are measured on the internal diameter of the pipe which you cannot see. When talking about pipe insulation, you need to go off the external diameter of the steel pipe.

For example, 32mm Steel Pipe size actually means you need 42mm insulation. 32mm is the internal diameter, and 42mm is the external diameter.

Measure the diameter of your pipe correctly and determine the thickness of insulation you need before you buy pipe insulation online.

The pipe insulation you choose should not be too small for the pipe you want to insulate. Go up one size if in doubt. A little additional space is ok, but if the insulation you choose is too tight, it can come open even if you use adhesive or tape to close it.

Length

Here's a quick rundown of the standard lengths of pipe insulation.

Kingspan Phenolic Pipe Insulation = 1m

Isover Fibreglass Pipe Insulation and Paroc Pipe Insulaion = 1.2m

Nitrile rubber insulation from K-Flex or polyethylene insulation like Armacell Tubolit are typically manufactured in lengths of 2 meters.

What types of pipe insulation should I choose?

There are many options available today. You can buy pipe insulation online or visit your local vendor. Some of the most commonly used pipe-lagging products include:

- Foam Pipe Insulation: The simplest of all insulation options, Tubolit Polyethene foam pipe lagging from Armacell, comes in lengths of 2m. They work well as loft pipe insulation as well as being used externally due to their closed cell structure, effectively preventing water ingress. Installing foam insulation is super easy too, they are usually snapped into place by using duct tape or PVC tape to seal them, especially on the bends and tees to prevent them from springing off.

- Nitrile rubber pipe lagging: Nitrile rubber lagging solution from KFlex insulation is available in 2-metre lengths. It comes in many forms, including unsplit tubes that you can slip onto the pipe in one, whole sheets and as pre-slit self-seal tubes. This versatile pipe insulation finds alot use in household plumbing and commercial HVAC application especially Air Conditioning systems.

- Phenolic Foam Pipe Insulation: Phenolic pipe insulation from Kingspan is one of the thinnest, most thermally efficient solutions available on the market today. This moisture-resistant pipe lagging can insulate all kinds of pipes in HVAC and building applications.

- Fibreglass and Rockwool Pipe Insulation: These 2 are collectively known as Mineral Wool insulation owing to the fact they are made from the minerals of Silica i.e glass or Basalt rock which are superheated and spun into fibres, hence the name Fibreglass for example. Mineral wool pipe insulation is one of the best options for dual use as acoustic insulation as well as thermal insulation. Pipes should be lagged with 20mm wall thickness at least in domestic properties.

Which pipe insulation is best?

Which pipe insulation is the best is subjective. It depends on what your goals are when choosing pipe insulation as all the different materials have different properties and therefore different outcomes.

When selecting pipe insulation, it is important to consider the desired outcome. Different materials have different properties, so choosing the right one depends on what goals you are trying to achieve.

For example, if you are looking for high-temperature insulation, you may choose a material such as Rockwool or ceramic. For the best thermal pipe insulation, you would be advised to use Phenolic foam insulation such Kingspan Kooltherm, which is the best insulator when it comes to heat loss.

If you are aiming for a low-cost insulation solution that still offers effective protection against heat loss, then foam insulation such as Tubolit or Armaflex lagging might be the best option.

On the other hand, if you need pipe wrap insulation that is also fire resistant, then you might want to look into using Rockwool or calcium silicate. With so many pipe insulation options available, it is important to consider your specific goals before making your decision.

Again if you are unsure, contact us and we will offer free advice or a local pipe insulation contractor.

How to check if your pipes are insulated?

Apart from doing a visual survey of pipework, another way is to use a thermal imaging camera to take pictures of the pipework to see where the heat loss is occurring the most.

It may point out dark corners of loft spaces for example where you couldn't see if there is lagging on pipes or not.

If you're in any doubt, then it's always best to get in touch with a professional pipe insulation contractor who can carry out an accurate survey of your property and provide you with an estimate of what needs to be done.

How to lag pipework yourself

Let's break this down into multiple steps because it's important that you get this right before charging ahead with lagging pipes as it may be to your detriment if you do so.

The steps are:

- Safety Considerations and Tools Needed

- Buying the right pipe insulation

- Checks to make prior to insulating your pipes.

- Actual Installation of the pipe insulation

Stay safe when working in loft spaces

When insulating water pipes in loft spaces, it is important to take into account the environment you will be working as it can be quite hazardous.

The first thing you need to be aware of is the floor in a loft space is usually, well, none existent! Meaning, there will probably be no proper floors for you to walk on, and only timber joists that are available to take your body weight.

Between the joists will be the ceiling of the room below which will normally be just plasterboarded, and these are not capable of supporting the weight of a person.

So with this in mind, you need to use boards to bridge the gap between the joists. It's also advisable to use a harness! This will protect you from falling down if something goes wrong or you lose your footing.

Make sure that the loft space is well-ventilated to prevent any potential health hazards caused by gases or dust from accumulating in the air.

Additionally, it is important to wear protective clothing, such as a face mask, gloves, and safety glasses alongside sturdy footwear with steel toe caps, to protect against breathing in fibres and getting things in your eyes, hands, and feet.

Finally, be aware of any potential trip hazards, such as cables (and Christmas decorations!), whilst making sure that the loft has adequate lighting to ensure the safety of all those working in it.

Tools Needed for lagging of pipes

- Measurement tape

- Fine Tooth Saw

- A sharp, Non-Serrated Knife such as a kitchen knife.

- Mitre box

- Duct tape, Foil Tape, or cable ties.

- Marker pen

Buying Pipe Insulation

The biggest factor in choosing the right pipe insulation is bore size.

It is rare to find solitary pipes in the loft area. Even if you spot a single pipe, it is usually attached to a wall or joist.

In places where two or more pipes are run close together or butted up against a wall, installing thick insulation can be difficult.

If it's difficult to lag pipes that are tight together or against a wall, then cutting away a strip from the pipe lagging and 'marrying' pipe insulation together may be your only option (That is basically taping them together)

You may discover pipes such as plastic overflows or metal gas pipes.

Plastic water pipes are much more flexible than metal pipes, making them less prone to breaking if water freezes. However, there's no harm in taking precautions and insulating these as well.

Which pipes need to be insulated?

In a nutshell, below are the 3 main types that are critical pipes to protect -

- You need to be insulating cold water pipes where the goal is to prevent condensation, heat gain and pipes from freezing leading to a burst pipe

- Insulating Heating pipes will prevent heat loss and radiators stay at the right temperature for longer with less energy.

- Insulating Hot water pipes wherever possible will help prevent heat loss too, meaning less energy use, hotter showers and protection against legionnaires disease,

1. Identify the type of pipework

The first step when dealing with pipes in your loft is to identify the type of pipes present. This is important, as it will determine what type of maintenance and repairs may be necessary. Commonly found in lofts are water pipes, gas pipes, and drainage pipes.

Water pipes are typically made of copper or plastic, while gas pipes are usually black or red in colour with yellow stripes and are made of steel or iron. However, gas pipes are also made from copper and may not have any markings to distinguish them.

Drainage pipes can be made of clay, cast iron, or plastic and are usually black or white.

Knowing the identity of pipes is a key element in making informed decisions about their upkeep and repair and whether they need insulating or not.

2. Check for potential leaks

After inspecting the pipes in the loft, it is important to check for any potential leaks. This can be done by gently pressing around the pipes and joints to feel for any wetness.

Furthermore, it is also a good idea to look for any signs of staining or discolouration on the pipes as this could indicate a potential leak. If any signs of a leak are present, it is important to address this issue as soon as possible to prevent further damage.

How to Buy Pipe Insulation Materials Online

Buying pipe insulation materials online can be a great way to save time and money. First, you need to research different types of insulation materials available and find the ones that best meet your needs.

Compare prices and read reviews to determine which products are of the highest quality and offer the most value for your money. Once you have identified the right product, select it and place it in your shopping cart.

Be sure to include all necessary information such as size, length, thickness, material type, etc., so that you can receive accurate pricing and delivery estimates from the seller. Finally, make payment and wait for your order to arrive at your doorstep!

How to lag pipes

Straight runs

Wipe the surface of the first length of pipe you're going to insulate with a clean cloth. Measure and note the length of the pipe. Now, using a sharp knife, preferably non-serrated or a small saw, cut the pipe insulation to the required length.

Open up the pre-cut slit and slip on the insulation to the pipe.

Seal the insulation together using duct tape (for tubolit and nitrile rubber), aluminium foil tape (for foil-faced pipe lagging) adhesive or a combination of all of them

When using self-seal insulation from K-Flex, simply slip the insulation over the pipe and remove the adhesive strips. Apply little pressure and join the insulation together by pushing the two sides together with your thumb to close up around the pipe.

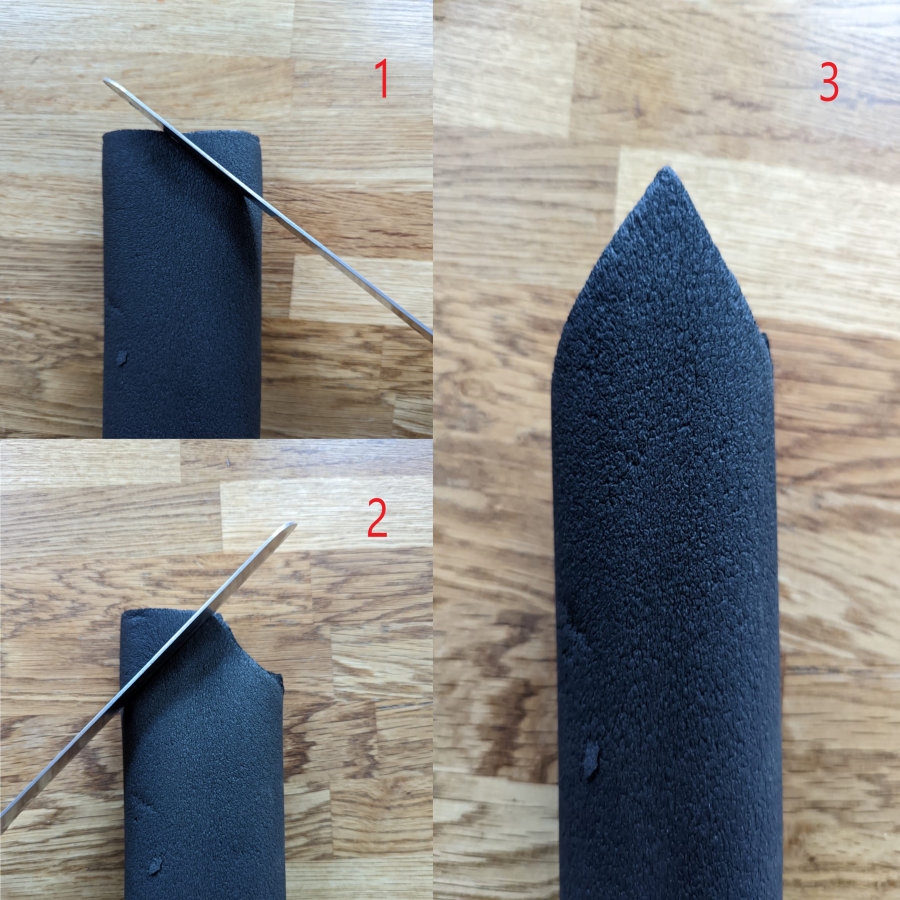

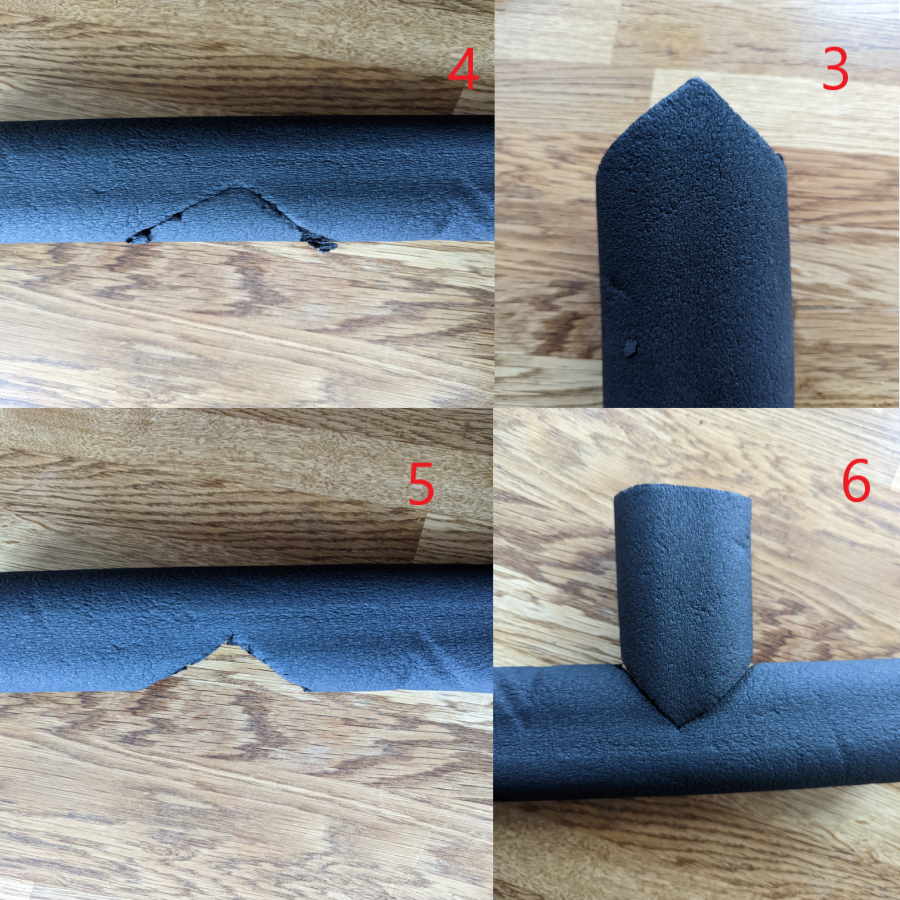

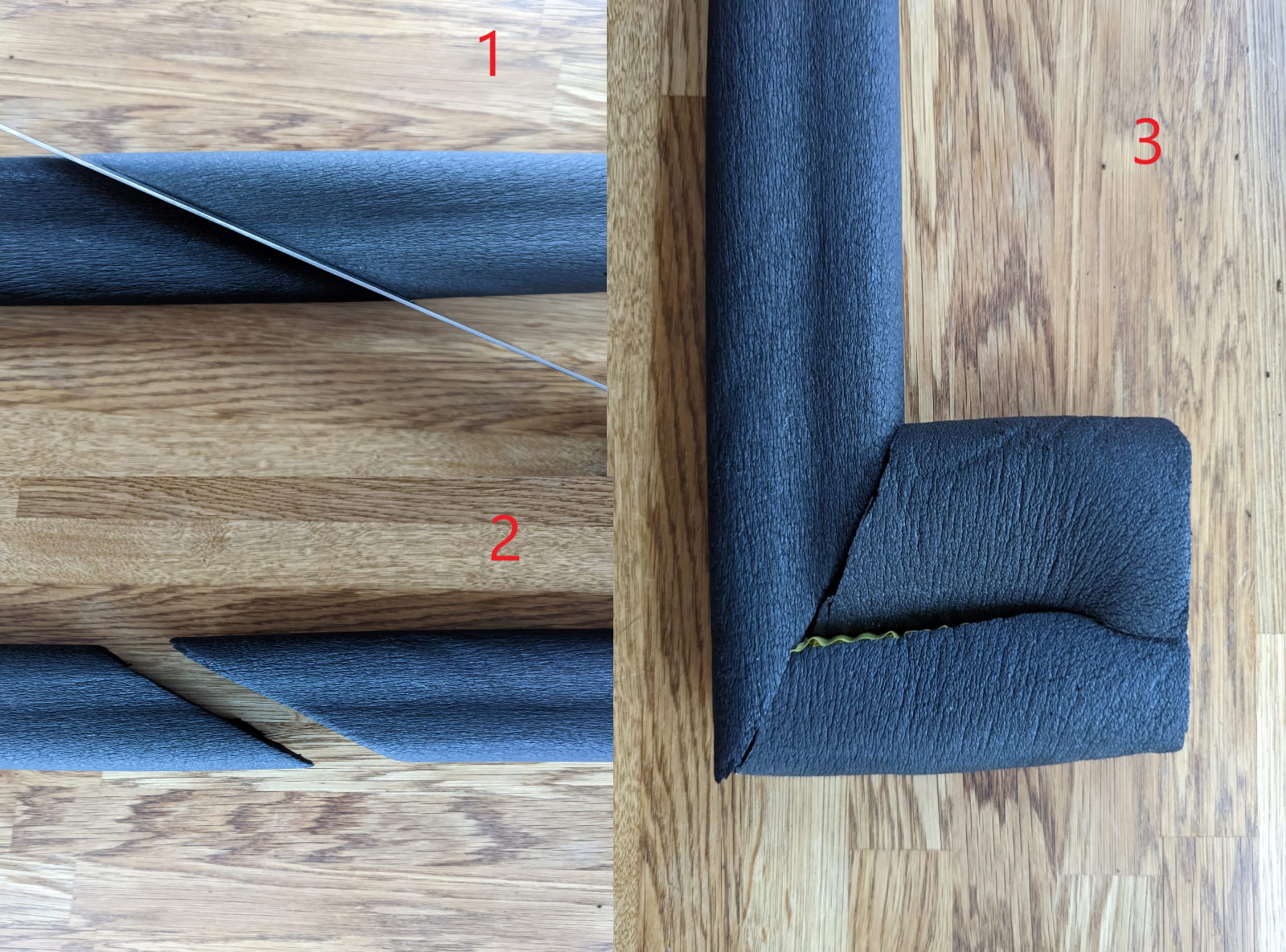

‘T’-Branches:

Make 2 x 90-degree wedge-shaped incisions in the pipe insulation of the main pipe (the top line horizontal line of the T). This will leave a gap that can be filled by the vertical part of the T, which will have what looks like an arrow head end to slot into the incision we previously made.

To make the arrow head point, cut the end of the tube that would be joined at 90° at two 45° angles. Now, insert the pointed end into the main tube's 90° cut-out. Wrap the duct tape around the T-piece to seal the junction.

90-Degree bends:

For a 90° bend in the pipe, that is when the pipe is turning a corner, cut the ends of the two lengths at a 45° angle. Attach both to the pipe at the 90° right-angle bend, with their 45° ends meeting. Use duct or foil tape to seal the junction.

You can find further instructions for insulating pipes on our blog.

Can you put loft insulation over pipes?

It depends on the reason why. If your doing it because your pipes are clipped to the joists and therefore you have no choice but to lay your loft insulation over it, then the answer is absolutely! Although it might be prudent to put some sort of sign to indicate there are pipes beneath the insulation in case a tradesman accidentally kneels on them for example.

However, if you saying laying loft insulation on top of pipes instead of actual pipe insulation then the answer is not really.

There is no way loft insulation will keep a pipe warm as well as proper pipe insulation which is designed for the job. It will also not prevent condensation from forming on the pipework because there is no vapour barrier in loft insulation like there is in pipe lagging.

Having said all that, if you simply cannot budget for pipe insulation then in this situation, some insulation around pipes is better than nothing, whether it be loft insulation or pipe insulation.

Trace heating can help prevent pipes from freezing

Trace heating involves wrapping electrical resistance heating cables around the pipes, which helps to keep them warm and prevents them from freezing over. This type of heating is also very efficient and cost-effective, as it only uses the energy needed to keep the pipes at a safe temperature.

Additionally, trace heating can be used on both metal and plastic pipes, making it a great choice for both residential and commercial applications.

Trace heating is also much safer than other methods of pipe insulation because it does not require any open flame or combustible materials. With trace heating, you can rest assured that your pipes will remain safe and functional throughout the cold winter months.

In conclusion:

And there you have it. pipe insulation saves them from freezing, reduces energy costs and increases the service life of your plumbing system.

By insulating pipes and water tanks in the loft area, you will not only ensure that your home is energy-efficient but also that the insulation laid in your loft remains dry. Just a few quid more, and you will have ensured energy saving in every way possible.

For everything, you need to insulate lofts, pipes and water tanks, visit Buy Insulation Online.

We deliver the best quality pipe insulation products for free in major cities and plant a tree for free on every order. If you are ever unsure of the right size of pipe insulation or valve jacket for you, you can request a call-back, and our experts will be happy to clarify your doubts.

Samuel Hitch

Managing Director

Buy Insulation Online.

Leave A Reply

Your feedback is greatly appreciated, please comment on our content below. Your email address will not be published. Required fields are marked *