Cavity Wall Insulation

Optimise your energy use, cut down on your bills and contribute to a more sustainable future with our top-notch cavity wall insulation. Enjoy browsing through our range, and don't hesitate to reach out to our friendly, knowledgeable team for any advice or assistance. Your journey to a well-insulated and energy-efficient home or office starts here, at Buy Insulation Online.

Similar Categories

A Comprehensive Guide to Cavity Wall Insulation

Providing an essential solution to homeowners in harnessing enhanced energy efficiency, cavity wall insulation plays a pivotal role in ensuring our homes are comfortable, warm, and environmentally friendly. It is a process that intricately involves filling the cavity or external wall of a house with insulation material. This guide will delve deeper into unravelling the world of cavity wall insulation.

The first cavity walls were introduced in the early 19th century, creating a dual exterior layer that can lead to a colder, less energy-efficient home if left uninsulated.

New homes typically have insulation get placed in the cavity walls as part of the construction process. If your property or commercial building was built between 1920 and 1990, this upgrade could be needed.

What is Cavity Wall Insulation and Why is it Essential?

Cavity wall insulation uses thermal methodologies to reduce heat loss and maintain a consistent indoor temperature profile. It fills the space with materials that prevent the air within the structure from undergoing convection.

Think of how a blanket helps to provide warmth at night while someone sleeps. The material stops the heat from escaping while also spreading it around the internal space.

The same outcome occurs within the building's structure when you insulate cavity walls.

Products are often available when searing for an "insulation shop near me" for an upcoming project. You can also find several options available through Buy Insulation Online to ensure the outcomes exceed every expectation.

Understanding the Concept of Cavity Wall Insulation

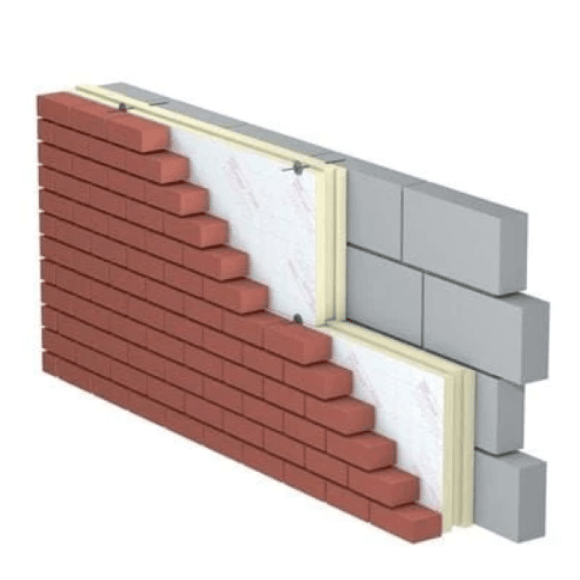

Cavity wall insulation is one of the primary methods of insulating homes, specifically designed for structures with a cavity wall or solid wall. The process involves an installer filling the wall cavity with insulation material, with options such as mineral wool or polystyrene beads being commonly used. Insulation installed into the cavity mitigates the transfer of heat, significantly improving the home's overall energy efficiency.

The Role of Cavity Wall Insulation in Energy Efficiency

Insulating the cavity walls of a home plays a significant role in overall energy savings. The energy saving trust commends the use of good insulation as it hampers heat loss from your home, reducing the energy expended on heating, eventually reducing energy bills. Effective installation of cavity insulation ensures better thermal regulation, with lower requirements for artificial heating or cooling.

Why Your Home Needs Cavity Wall Insulation

Without suitable cavity wall insulation, a home is susceptible to losing a significant portion of its heat through the walls, leading to a rise in energy bills. Moreover, a poorly insulated home can be affected by damp due to external weather conditions. Insulating cavity walls effectively combats this concern while also contributing towards climate change efforts through reduced carbon emissions.

Is Your Home Suitable for Cavity Wall Insulation?

Identifying if Your Home Has Cavity Walls

Identifying if Your Home Has Cavity Walls

Determining if your home has cavity walls involves looking at the year it was built, its material type, and its construction method. Homes built after the 1920s typically have cavity walls.

You can inspect the brick pattern to see if it is a cavity wall. Review the external walls for a regular batter of alternating headers and stretchers. That indicates you have a cavity wall because solid ones typically keep a consistent pattern.

Weep holes allow moisture to drain from the cavity, which is a feature that solid walls do not require.

If you are still trying to figure it out, it's best to consult with a qualified surveyor or structural engineer. These professionals will conduct a thorough inspection and provide a definitive answer regarding the type of walls in the property.

The Role of Wall Construction Year in Cavity Wall Suitability

The year your home was built plays an instrumental role in determining its suitability for cavity wall insulation. Older homes, pre-1920s, generally have solid rather than cavity walls, which means normal cavity insulation cannot be installed, but there are other alternatives available.

Issues that May Occur With Your Cavity Wall

Prior to getting cavity wall insulation installed, it's important to rule out existing issues with the wall that could complicate the process. These issues may include dampness, wall ties deterioration, or a badly fitted cavity wall. An experienced installer can assess these factors during their initial survey. You can watch our video on this subject which can be found below

Exploring the Different Types of Cavity Wall Insulation - Insulation Material Options for Cavity Walls

Insulation Material: From Mineral Wool to Polystyrene Beads

Several types of cavity insulation material can be used to fill the cavity, from mineral wool to polystyrene beads and more, each having relative advantages and their efficiencies. Typically, the insulation material is pumped into the cavity, covering the entire space to ensure no gaps are left unfilled with insulation. Read our blog on potential problems with cavity wall insulation.

Comparing Cavity Wall Insulation and Loft Insulation

While both loft insulation and cavity wall insulation aim to enhance the home's energy efficiency, they perform different roles. Loft insulation aims to prevent heat loss through the roof, whereas cavity wall insulation targets heat loss through the walls. Therefore, choosing the correct insulation type is instrumental to achieve the desired level of warmth and energy efficiency.

Choosing the Right Type of Insulation for Your Cavity Walls

An insulation installer can guide you on the right choice based on the year your home was built, the type of brick used, and the presence of any wall issues like damp. Professional advice from a national insulation association or cavity insulation guarantee agency recommended installer can ensure your insulation is effective and durable.

A high-quality insulation batt or roll offers several material choices for a cavity wall. Whether renovating a property or getting close to finishing a new home or commercial structure, these additional options can help to complete the project while meeting building codes and zoning expectations.

-

Fibreglass Insulation. This choice is common because of its flexibility, wide availability, and high U-value rating. It is also reasonably affordable so if your looking for cheap cavity wall insulation, fibreglass will probably be your best bet.

-

Natural Fibres. Full-fill cavity insulation with products like hemp, cotton, or flax offer low-carbon installation options while having a competitive outcome to other materials in batts and rolls.

-

Cellulose. This plant fibre is excellent insulation for cavity walls. It reduces noise once installed while reducing air leaks. Its not used as extensively as it once was in the UK.

-

Mineral Wool. Although it looks like an animal product, this insulation is made from raw materials like stone or rock wool. The items get melted and then spun into fibres that resemble wool for insulating purposes. It is often more prevalent than fibreglass.

-

Phenolic Foam. This foam cavity wall insulation is made from rigid phenolic resin. It has excellent thermal properties, high fire resistance, and is easily installed to create a uniform layer.

-

PIR Cavity Wall Insulation. Composed of a foam core sandwiched between two facings, this insulation choice for cavity walls adds strength while creating a vapour barrier.

Fibreglass batts are popular for cavity walls because the material is non-combustive. Since it does not burn, it can withstand high temperatures without worrying about toxic gas releases or contributing to the fire. It achieves these outcomes without significant settling or deterioration, ensuring the expected thermal performance continues for several years.

A final choice is to use polystyrene granules. These "beads" are lightweight, making the product easy to handle during installation. This trait also reduces the load on the building's structure. The granules are poured into the cavity, filling gaps effectively to ensure complete coverage while reducing thermal bridging.

What Are Wall Cavity Insulation Batts?

Wall cavity insulation batts are pre-cut sections of insulation material (often fiberglass, rock wool, or cellulose) that are designed to fit into the cavities between the walls of a building. These batts help to reduce heat loss and can improve the energy efficiency of the home.

Wall cavity insulation batts are pre-cut sections of insulation material (often fiberglass, rock wool, or cellulose) that are designed to fit into the cavities between the walls of a building. These batts help to reduce heat loss and can improve the energy efficiency of the home.

Cavity wall batts play a significant role in preventing the transfer of heat and sound through the walls, thereby providing thermal and acoustic insulation.

Batt insulation requires some technical knowledge to install because of its shape and handling requirements.

More cutting and shaping are often necessary when using an insulation roll instead of batts for cavity walls.

Is Polyurethane Spray Foam Appropriate for Cavity Walls?

Polyurethane foam has excellent insulating properties and can provide effective thermal insulation when installed correctly in cavity walls. It requires contractor oversight to ensure it meets the current code, which is not a requirement for insulation batts.

Closed-cell polyurethane foam is typically more moisture-resistant than open-cell foam, as it uses a structure that restricts air and moisture movement. It creates a continuous barrier.

With open-cell foam, air can fill the empty spaces inside the material. This design reduces the cost of cavity wall insulation projects while offering a softer, more flexible result.Those characteristics mean moisture passes through it more easily, but that can be an advantage when managing it in the cavity wall is essential.

Some specific challenges must be addressed to ensure the product is installed safely.

Polyurethane foam insulation is a combustible material that can contribute to fire spread if not adequately protected. Building codes often require the use of fire-retardant coatings or barriers when using this product.

Some foam types contain blowing agents that might not meet individual or community expectations for global warming potential. If you hire a contractor to install this product, ask about water-blown and low-gas choices to ensure the project aligns with personal sustainability goals.

50mm vs 100mm Cavity Wall Insulation

Investing in 50mm cavity wall insulation will provide some level of thermal resistance and help reduce heat loss. Its thermal performance might not be as high as a 100mm alternative.

If your cavity space is limited in width, a 50mm product might be the only available option.

50mm insulation is generally less expensive than thicker options. If cost is a significant factor for an upcoming project, sizing could be a consideration.

With cavity wall insulation 100mm thick, the thicker product provides improved thermal resistance and energy efficiency gains. The outcome reduces heating and cooling costs by preventing heat loss.

Although 100mm products are often more expensive than cavity wall insulation at 50mm, the potential long-term savings can offset the initial investment. Energy bill reductions over an extended period often let these thicker batts pay for themselves eventually.

Some properties experience more extreme temperatures, including hot summers and cold winters. Isover cavity wall insulation at 100mm is a high-quality product that achieves these results.

What About Rockwool Cavity Wall Insulation

Rockwool cavity wall insulation is a semi-rigid mineral wool insulation board. It is designed for rainscreen and exterior applications.

The mineral wool is made from basalt or volcanic rock. It gets melted and spun into compressed fibres to form the boards or cavity walls insulation batts.

It works by trapping air within its structural fibres, creating a barrier that reduces heat transfers. Like fibreglass insulation batts, Rockwool is non-combustible so it does not contribute to a fire spreading.

This product is also resistant to moisture, preventing water absorption and the subsequent deterioration of the insulation's performance.

Benefits of Choosing a Cavity Wall Insulation Board

Cavity wall insulation boards offer several benefits when compared to other material choices. The most significant advantage involves moisture resistance, helping to prevent mould growth and dampness within the walls to promote a healthier environment.

Cavity wall insulation boards offer several benefits when compared to other material choices. The most significant advantage involves moisture resistance, helping to prevent mould growth and dampness within the walls to promote a healthier environment.

This trait reduces condensation issues that can develop within the cavity walls with other materials. By creating a thermal barrier, these boards prevent the warm indoor air from encountering the cold wall surface, reducing the likelihood of moisture droplets forming.

Cavity insulation boards are typically thin and compact, which makes them an excellent choice when space is limited. They slip in easily and deliver consistent results.

For more information on how to make an informed choice when buying cavity wall insulation online, please the video we made on the subject below

Getting Cavity Wall Insulation Installed: Choosing the Right Installer

What to Look for in a Cavity Wall Insulation Installer

When selecting an installer, you must ensure they are a reputable and certified professional who is well-versed with cavity wall insulation installation. Essential factors to consider include their experience, the quality of materials they use, their professional credentials, and the presence of a robust insulation guarantee.

The Process of Installation: From Assessment to Finishing

The process of installing cavity wall insulation typically commences with an initial assessment of the property. Post assessment, the installer will commence work by drilling holes in your wall and injecting the insulation material into the cavity. Once the cavity is filled with insulation, the installer will finalize the procedure by sealing any drilled holes.

Exploring the Cavity Wall Insulation Grant and Free Cavity Wall Insulation Options

UK residents have access to various grants, such as the free cavity wall insulation grant, aimed at reducing the financial burden of the insulation process. Additionally, income-based grants or local government grants to conserve energy, including local council schemes, can be explored to achieve costs savings on insulation.

How to Insulate a Cavity Wall

Insulation for cavity wall designs helps to improve the energy efficiency of a home or commercial property by reducing heat loss.

Although every structure is unique, these general steps deliver positive results when followed for those installing cavity wall slab insulation.

Step 1: Check for Suitability

Some cavity wall designs are not well-suited for this insulation type. Older buildings might not have enough space or depth between the exterior surfaces to obtain an appropriate U-value rating for the property.

Step 2: Choose the Material

Several insulation materials are available for cavity walls. Some products are more appropriate than others since each property is unique. Building codes might dictate some decisions, but it is usually your personal and budgetary preferences that help to decide the best option to install.

Step 3: Know Your Limits

Most people can install cavity insulation batts without professional help. Since this investment is a crucial component of a property’s infrastructure, it is also essential to know one’s personal capabilities.

If a task is beyond personal skills or requires additional tools, hiring an experienced professional to complete the work might be more appropriate.

Step 4: Conduct a Pre-Inspection

Before installing cavity batt insulation or rolls, look at the space to ensure it is clean and suitable for the preferred material. Look for dampness or structural issues that must be addressed before proceeding with the installation process.

Step 5: Place the Insulation

Fill the open area with cavity wall insulation batts or a similar product that delivers the U-value required for the home or commercial property. It helps to start at the bottom and work upward to ensure the product stays in place while working.

Step 6: Drill, Inject, and Seal (Optional)

Some insulation options for cavity walls get injected into the space from the exterior after the finishing work is complete. Small holes are drilled into the first layer to place the product in its intended space between it and the “second” exterior.

After injecting the insulation, the holes are filed and sealed with colour-matching materials to make the finished work less noticeable.

Step 7: Clean Up

After installing the insulation wall batts in the cavity, it is time to remove any debris or materials that may have accumulated during the process, ensuring your property is left tidy and safe.

Should I Use Full Fill PIR Cavity Insulation?

A fully filled masonry cavity wall is a design technique used primarily to boost the thermal insulation of a building and also to prevent wind-driven rain reaching the internal skin..

A fully filled masonry cavity wall is a design technique used primarily to boost the thermal insulation of a building and also to prevent wind-driven rain reaching the internal skin..

However, filling the cavity with insulation can potentially create a pathway for moisture to travel from the outer leaf to the inner leaf of the wall, which is why the role of BBA (British Board of Agrément) certification is so critical. The BBA is a UK-based organisation that provides certification for construction products and systems, including cavity wall insulation.

Accreditation from a third-party, indicated by a BBA certification, assures that the insulation effectively prevents the intrusion of wind-driven rain across the cavity. As a result, the wall continues to fulfil its fundamental purpose of keeping the inner layer of the structure dry, as long as it's installed, utilised, and maintained as outlined in the certificate.

Receiving BBA certification signifies that a product has undergone rigorous testing and evaluation, verifying its performance in terms of durability, safety, and effectiveness against moisture penetration. It demonstrates that the insulation will indeed block wind-driven rain from penetrating the cavity, thus ensuring the dryness of the inner leaf of the wall. However, this protection is only guaranteed if the insulation is installed correctly, used appropriately, and maintained according to the guidelines specified in the certificate.

This system offers an effective solution to optimise the thermal performance of buildings while ensuring structural integrity and internal dryness, provided it's implemented and maintained as per the recommended guidelines.

Some manufacturers create high-quality wall insulation boards by implementing a composite design. One of the most popular choices in this category contains a PIR core to offer a higher U-value rating.

These boards offer gas-tight facings with one side bonded to a profiled skin during the creation process. This process ensures an appropriate drainage plane is available, ensuring any moisture penetrating the exterior wall travels down the protective facing and to the external leaf.

Full fill cavity insulation offers excellent protection for homes and buildings facing wind-driven rain issues during the year.

Costs and Savings Associated with Cavity Wall Insulation

Calculating Insulation Costs: Initial Investment and Long-Term Savings

Although the installation cost of cavity wall insulation can be substantial, the long-term energy bill savings will compensate for this initial outlay. Moreover, various insulation schemes, like the ECO scheme, can help reduce the upfront cost, while the potential for a cavity wall insulation grant can further ease the expense.

Cavity wall insulation prices vary enormously depending on the material. In general, fibreglass is cheaper than Rockwool or cavity foam insulation like PIR and phenolic, with phenolic typically being the being the most expensive.

The Effect of Cavity Wall Insulation on Energy Bills

Installing cavity wall insulation exhibits a pronounced effect on energy bills. Reductions in energy consumption lead to decreased bills and a smaller carbon footprint, reaffirming the financial sense of insulating homes correctly. The energy-saving trust asserts the potential for large annual savings on heating bills post-insulation installation.

Understanding the Insulation Guarantee and its Financial Implications

The cavity insulation guarantee agency provides a 25-year guarantee on the insulation installed, ensuring that you can have peace of mind about the quality and effectiveness of your insulation for many years to come. Financially, this represents significant future savings.

Cavity Wall Insulation Is an Economical Investment

Insulation in cavity walls offers an effective way to protect your exterior from precipitation damage while creating a more comfortable interior. By improving the structure’s heat retention properties and encouraging moisture restriction and movement, this investment often pays for itself for many homeowners.

For 19th-century homes, cavity wall insulation at 100mm is often the best choice. The design and spatial requirements can differ for each property, so consider the gap before looking for the best batts or boards.

Conclusion

Get cavity wall insulation sheets from big brands like Knauf, Rockwool, Celotex, and Superglass at Buy Insulation Online.

If you have any questions, please feel free to reach out to one of our friendly representatives at your convenience to get the answers you need about cavity wall insulation.

More Resources On Wall Cavity Insulation

You can see some videos we have made on cavity insulation on our Youtube Channel here - Problems With Cavity Wall Insulation / Cavity Wall Insulation - Buyer’s Guide

We have also written extensive articles on the subject which you can find here - Problems With Cavity Wall Insulation / The Advantages Of Knauf Cavity Wall Insulation For Your Home / Why Dritherm Is An Excellent Choice For Cavity Walls / Cavity Wall Insulation - Buyer’s Guide / Everything You Need To Know About Cavity Wall Insulation / Retrofit Cavity Wall Insulation - What You Need To Know

Take a look at some of the manufacturer's official websites here -

Knauf Dritherm 32 - https://www.knaufinsulation.co.uk/products/dritherm-cavity-slab-32

Knauf Dritherm 37 https://www.knaufinsulation.co.uk/products/dritherm-cavity-slab-37

Celotex Thermaclass https://insulation-uk.com/products/thermaclass-cavity-wall-21

Superglass Superwall 32: https://www.superglass.co.uk/products/superwall-32-cavity-wall-batt/

Superglass Superwall 36: https://www.superglass.co.uk/products/superwall-36-cavity-wall-batt/

Kingspan Phenolic Cavity Wall Insulation - Kooltherm K108 Cavity Board : https://www.kingspan.com/gb/en/products/insulation-boards/wall-insulation-boards/kooltherm-k108-cavity-board/

FAQ's

Q: What is a cavity wall insulation installer?

A: A cavity wall insulation installer is a professional who installs cavity wall insulation in homes. They drill holes in the external walls of a house and fill it with insulation material, such as polystyrene beads, into the cavity. Installers should be certified by the National Insulation Association or the Cavity Insulation Guarantee Agency to ensure proper installation.

Q: How do I know if my home is suitable for cavity wall insulation?

A: To determine if your home is suitable for cavity wall insulation, an installer will survey your property. They would consider the year your home was built, the type of walls your home has (solid wall or cavity), the current state of the wall cavity and if there're any damping issues. Homes built after the 1920s are likely to have a wall cavity suitable for insulation.

Q: How much does insulation costs and savings account for?

A: The cost of installing cavity wall insulation varies depending on the size of your house and the insulation material used. However, the Energy Saving Trust estimates that the average installation cost is around £500. Full insulation of a property can lead to annual energy bill savings of up to £275.

Q: Can I receive a cavity wall insulation grant to cover the installation costs?

A: Yes, the government and energy providers offer a free cavity wall insulation grant under the ECO scheme. This grant intends to encourage energy-saving measures and can cover the full cost of having cavity wall insulation installed. The installer or energy provider can guide you through the application process.

Q: What happens if there are any issues with your cavity wall after the insulation was installed?

A: If issues occur after insulation installation, you should immediately contact your insulation installer. Installations are usually covered by a 25-year guarantee from the Cavity Insulation Guarantee Agency, provided that the installer is certified. They will examine any issues such as damp and wall ties and offer a solution or repair.

Q: What are the types of insulation material used for cavity wall installation?

A: The most common types of insulation material used for cavity wall installation are mineral wool, polystyrene beads and foam insulation. The choice of material depends on the specific property needs and the installer’s expertise.

Q: What is the difference between loft insulation and cavity wall insulation?

A: Loft insulation is installed in the roof area of a home to prevent heat loss, while cavity wall insulation is installed in the walls of a home to maintain a steady indoor temperature and reduce energy consumption. Both types of insulation work towards energy efficiency but are installed in different areas of a home.

Q: Does the cavity wall insulation installation alter the appearance of my home?

A: No, cavity wall insulation does not change the appearance of your home. The installer will drill holes discreetly on the external wall, in the joint of the bricks, then they will fill the wall with insulation and finish by filling any drilled holes with cement that matches your wall.

Q: Can every wall of my house get cavity wall insulation?

A: Only walls with a cavity, typically outer walls, can get cavity wall insulation. Inner walls or solid walls without a cavity are not suitable for this type of insulation. An installer can assess your home and advise on the best type of insulation for each area of your house.

Q: Are there cases when insulation cannot be installed?

A: Yes, in some cases, insulation cannot be installed. For instance, if the wall cavity has any dampness or if the cavity is contaminated with building debris, insulation installation is not advisable. A professional survey by an insulation installer can identify these issues prior to installation.