Concrete floor insulation

Insulating under concrete floors can help keep rooms warmer in winter and cooler in summer. It helps to reduce energy costs, as heated or cooled air is less likely to escape through the floor. Insulating also reduces noise from adjacent rooms, making it more comfortable for family members and reducing sound transmission from neighbours. Finally, it keeps your feet cosy and warm.

Similar Categories

Using EPS and PIR insulation under concrete floors

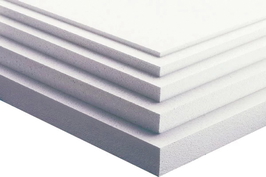

Polystyrene insulation, also known as EPS (expanded polystyrene) or Styrofoam insulation, is a type of plastic foam that is commonly used to insulate buildings. It is lightweight, moisture resistant, and has a high R-value, making it an effective insulator.

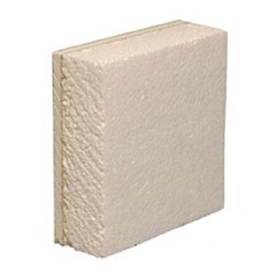

PIR (polyisocyanurate) insulation is a type of foam insulation that is made from a closed-cell foam core that is coated with a reflective foil on both sides. It is commonly used to insulate buildings, and it can be used below a concrete slab to insulate the ground floor.

Why are EPS and PIR good to be used as concrete floor insulation?

EPS and PIR can both be used below a concrete slab to insulate the ground floor of a building. One important property of EPS and PIR insulation is their compressive strength, which refers to their ability to withstand compressive forces or loads.

The compressive strength of polystyrene insulation is typically measured in pounds per square inch (psi). Different types of polystyrene insulation have different compressive strengths, with higher densities typically having higher compressive strengths.

For example, EPS and PIR insulation with a density of 1.5 pounds per cubic foot (pcf) may have a compressive strength of 25 psi, while polystyrene insulation with a density of 2.0 pcf may have a compressive strength of 35 psi.

The compressive strength of polystyrene insulation is an important factor to consider when selecting insulation for a building project.

In general, the higher the compressive strength, the more capable the insulation will be of resisting compressive forces or loads. This is particularly important for insulation that will be used below a concrete slab or in other applications where it will be subjected to heavy loads

To use PIR / EPS insulation below a concrete slab, it is typically installed on top of the subgrade (the ground beneath the slab) before the concrete is poured. The insulation is cut to fit between the edges of the slab and any walls or columns, and it is held in place with adhesive or pins. Once the insulation is in place, the concrete is poured on top.

Benefits of concrete ground floor insulation

There are several benefits to using EPS / PIR insulation below a concrete slab. One of the main benefits is increased energy efficiency. Polystyrene insulation has a high R-value, which means it has a high resistance to heat flow.

There are a few considerations to keep in mind when using EPS / PIR insulation below a concrete slab. One is the thickness of the insulation. In general, the thicker the insulation, the better the insulation performance will be.

However, it's important to balance the thickness of the insulation with the height of the finished floor. If the insulation is too thick, it could cause the finished floor to be too high.

Another consideration is the type of adhesive or pins used to hold the insulation in place. It's important to use a high-quality adhesive or pins that are specifically designed for use with polystyrene insulation. This will help to ensure that the insulation stays in place during the pouring of the concrete or screed and performs at its best.

EPS / PIR insulation can be used below a concrete slab to insulate the ground floor of a building. They are lightweight, moisture resistant, and has a high R-value, making it an effective insulator.