Pre Insulated Ducting

Similar Categories

Pre Insulated Ducting: A Guide to Choosing and Installing the Best Solution for Your HVAC System

If you are looking for a way to improve the efficiency and performance of your heating, ventilation, and air conditioning (HVAC) system, you may want to consider pre insulated ducting. Pre insulated ducting is a type of ductwork that has insulation material already attached to it, making it easier and faster to install. Pre-insulated ducting can offer many benefits, such as:

- Reducing energy loss and saving money on your utility bills

- Enhancing indoor air quality and comfort by preventing condensation and mould growth

- Minimising noise and vibration from the HVAC system

- Providing fire resistance and thermal stability

- Reducing the weight and space of the ductwork

- Simplifying the design and installation process

However, not all pre insulated ducting products are created equal. There are different types, sizes, shapes, and materials of pre-insulated ducting available in the market, and you need to choose the one that suits your specific needs and preferences.

In this article, we will guide you through the process of choosing and installing the best pre insulated ducting solution for your HVAC system.

What is Pre Insulated Ducting?

Pre insulated ducting is a type of ductwork that consists of a rigid or flexible inner core that carries the airflow, and an outer layer of insulation material that covers the core. The insulation material can be made of various materials, such as polyurethane (PUR), polyisocyanurate (PIR), mineral wool, or fibreglass. The insulation material can also have different thicknesses, densities, and thermal conductivities, depending on the level of insulation required.

Pre insulated ducting is a type of ductwork that consists of a rigid or flexible inner core that carries the airflow, and an outer layer of insulation material that covers the core. The insulation material can be made of various materials, such as polyurethane (PUR), polyisocyanurate (PIR), mineral wool, or fibreglass. The insulation material can also have different thicknesses, densities, and thermal conductivities, depending on the level of insulation required.

The main advantage of pre insulated ducting is that it eliminates the need for separate insulation and cladding of the ductwork, which can be time-consuming, costly, and labour-intensive. Pre insulated ducting can be installed in one step, saving installation time, and reducing waste. Pre insulated ducting can also provide better thermal performance and air tightness than conventional ductwork, as there are no gaps or joints between the insulation and the duct.

How to Choose the Right Pre Insulated Ducting for Your HVAC System?

There are several factors that you need to consider when choosing the right pre insulated ducting for your HVAC system, such as:

- The size and shape of the ductwork

- The air flow rate and pressure

- The temperature and humidity of the air

- The acoustic and fire requirements

- The environmental and health standards

- The budget and availability

One of the most important factors is the size and shape of the ductwork, as it determines the amount of air that can be delivered and the space that can be occupied.

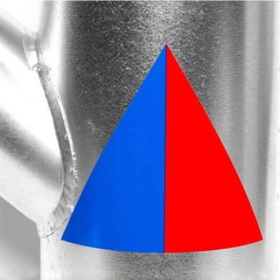

Pre insulated ducting can come in various shapes, such as round, rectangular, or flat oval. Round ducts are the most common and efficient shape, as they have the lowest surface area and friction loss. Rectangular ducts are more suitable for tight spaces and low ceilings, as they can fit into corners and edges.

Flat oval ducts are a compromise between round and rectangular ducts, as they have a lower height than round ducts and a lower width than rectangular ducts.

Another important factor is the air flow rate and pressure, as they affect the performance and durability of the ductwork. Pre insulated ducting can have different types of inner cores, such as rigid or flexible. Rigid cores are made of metal or plastic, and they can withstand higher air pressures and velocities.

Flexible cores are made of fabric or plastic, and they can bend and adapt to different shapes and angles. Rigid cores are more suitable for high-pressure and high-velocity applications, such as commercial and industrial buildings. Flexible cores are more suitable for low-pressure and low-velocity applications, such as residential and small commercial buildings.

The temperature and humidity of the air also play a role in choosing the right pre insulated ducting, as they affect the condensation and mould growth potential. Pre insulated ducting can have different types of insulation materials, such as PUR, PIR, mineral wool, or fibreglass. PUR and PIR are synthetic materials that have high thermal resistance and low water absorption, making them ideal for hot and humid climates.

Mineral wool and fibreglass are natural materials that have lower thermal resistance and higher water absorption, making them more suitable for cold and dry climates.

The acoustic and fire requirements are also important, as they affect the safety and comfort of the occupants.

Pre insulated ducting can have different levels of noise reduction and fire resistance, depending on the type and thickness of the insulation material. Generally, thicker and denser insulation materials can provide better noise reduction and fire resistance than thinner and lighter insulation materials. However, thicker and denser insulation materials can also increase the weight and cost of the ductwork.

The environmental and health standards are also relevant, as they affect the sustainability and quality of the ductwork. Pre-insulated ducting can have different levels of environmental impact and health risk, depending on the type and origin of the insulation material.

Generally, natural and recycled insulation materials can have a lower environmental impact and health risk than synthetic and virgin insulation materials. However, natural and recycled insulation materials can also have lower thermal performance and durability than synthetic and virgin insulation materials.

The budget and availability are also crucial, as they affect the feasibility and convenience of the ductwork. Pre insulated ducting can have different prices and availability, depending on the type and quality of the insulation material.

Generally, synthetic and virgin insulation materials can have higher prices and lower availability than natural and recycled insulation materials. However, synthetic and virgin insulation materials can also have higher thermal performance and durability than natural and recycled insulation materials.

How to Install Pre Insulated Ducting for Your HVAC System?

Once you have chosen the right pre insulated ducting for your HVAC system, you need to install it properly to ensure its optimal performance and longevity. The installation process can vary depending on the type and shape of the pre insulated ducting, but there are some general steps that you need to follow, such as:

- Measuring and marking the location and layout of the ductwork

- Cutting and fitting the pre insulated ducting sections and fittings

- Sealing and joining the pre insulated ducting sections and fittings

- Supporting and securing the pre insulated ducting sections and fittings

- Testing and commissioning the pre insulated ducting system

Measuring and marking the location and layout of the ductwork is the first step, as it helps you plan and prepare the installation. You need to measure and mark the dimensions and angles of the ductwork, as well as the locations of the air outlets, inlets, and terminals.

You also need to consider the clearance and accessibility of the ductwork, as well as the alignment and coordination with other services and structures.

Cutting and fitting the pre insulated ducting sections and fittings is the second step, as it helps you shape and connect the ductwork. You need to cut and fit the pre insulated ducting sections and fittings according to the measurements and markings, using the appropriate tools and methods.

You also need to ensure that the pre insulated ducting sections and fittings are compatible and consistent, as well as free from defects and damages.

You also need to ensure that the pre insulated ducting sections and fittings are compatible and consistent, as well as free from defects and damages.

Sealing and joining the pre insulated ducting sections and fittings is the third step, as it helps you seal and join the ductwork. You need to seal and join the pre insulated ducting sections and fittings using the appropriate materials and methods, such as tape, glue, screws, or clamps. You also need to ensure that the pre insulated ducting sections and fittings are air tight and leak proof, as well as thermally and mechanically stable.

Supporting and securing the pre insulated ducting sections and fittings is the fourth step, as it helps you support and secure the ductwork. You need to support and secure the pre insulated ducting sections and fittings using the appropriate materials and methods, such as hangers, brackets, straps, or rods. You also need to ensure that the pre insulated ducting sections and fittings are level and straight, as well as flexible and resilient.

Testing and commissioning the pre insulated ducting system is the final step, as it helps you test and commission the ductwork. You need to test and commission the pre insulated ducting system using the appropriate instruments and procedures, such as pressure gauges, flow meters, thermometers, or smoke generators. You also need to ensure that the pre insulated ducting system meets the design specifications and performance criteria, as well as the safety and quality standards.

Where to Buy Pre Insulated Ducting for Your HVAC System?

If you are looking for a reliable and reputable source of pre insulated ducting for your HVAC system, you may want to check out our website Buy Insulation Online, we are a leading online supplier of insulation products in the UK. We at Buy Insulation Online offer a wide range of pre insulated ducting products, such as:

- Stornch Induct Pre Insulated Ductwork: A high-quality pre insulated ducting system that consists of a rigid PIR core and an aluminium foil facing. It has excellent thermal and acoustic properties, as well as high fire resistance and air tightness. It is easy to install and maintain, and it comes in various sizes and shapes, such as round, rectangular, or flat oval.

- Flexible Insulated Ducting: A versatile pre insulated ducting system that consists of a flexible polyester core and a polyethylene insulation. It has good thermal and acoustic properties, as well as high flexibility and adaptability. It is ideal for low-pressure and low-velocity applications, and it comes in various diameters and lengths.

- Stornch Induct Pre Insulated Ducting Bends and Tees: A convenient pre insulated ducting system that consists of preformed bends and tees that can connect the straight sections of the ductwork. It has the same thermal and acoustic properties, fire resistance, and air tightness as the Stornch Induct Pre Insulated Ductwork. It is easy to install and adjust, and it comes in various angles and diameters.

Buy Insulation Online also offers a fast and secure delivery service, a friendly and helpful customer support team, and a competitive and affordable pricing policy. You can browse and order our pre insulated ducting products online, or contact us for more information and advice.

Conclusion

Pre insulated ducting is a smart and efficient solution for your HVAC system, as it can reduce energy loss, enhance indoor air quality and comfort, minimise noise and vibration, provide fire resistance and thermal stability, reduce the weight and space of the ductwork, and simplify the design and installation process.

However, you need to choose the right pre insulated ducting for your HVAC system, based on the size and shape of the ductwork, the airflow rate and pressure, the temperature and humidity of the air, the acoustic and fire requirements, the environmental and health standards, and the budget and availability.

You also need to install the pre insulated ducting properly, following the steps of measuring and marking, cutting and fitting, sealing and joining, supporting and securing, and testing and commissioning. If you are looking for a reliable and reputable source of pre insulated ducting, you may want to check out our website Buy Insulation Online, we are a leading online supplier of insulation products in the UK.

Frequently Asked Questions

Q: Are there specific connectors or accessories required for pre-insulated ducting installation?

A: Yes, pre-insulated ducting may require specific connectors, dampers, and mounting accessories to ensure a complete and effective installation for your HVAC system.

Q: Is there a specific diameter available for pre-insulated ducting?

A: Pre-insulated ducting is available in various diameters, including 125mm and 160mm, to accommodate different ventilation requirements.

Q: How does pre-insulated ducting contribute to energy efficiency in industrial settings?

A: Pre-insulated ducting plays a crucial role in industrial settings by providing insulation while minimizing air leakage, leading to improved energy efficiency and reduced heat loss.

Q: What are the key properties of pre-insulated ducting that make it suitable for HVAC and building services?

A: The key properties of pre-insulated ducting, such as its lightweight construction, self-sealing insulation, and compliance with building regulations, make it perfect for meeting HVAC and building service requirements.

Q: Is there a specific installation process for pre-insulated ducting?

A: The installation of pre-insulated ducting involves connecting the ductwork using suitable connectors and ensuring proper sealing and insulation to meet the specific requirements of the HVAC system. It is recommended to seek professional assistance for the installation process.