Flexible Ducting

Similar Categories

Flexible Ducting: A Guide to Choosing and Installing the Right Ducts for Your HVAC System

If you are looking for a way to improve the efficiency and performance of your heating, ventilation, and air conditioning (HVAC) system, you might want to consider flexible ducting. Flexible ducting is a type of ductwork that can bend and twist to fit any space, making it ideal for complex or irregular layouts. Flexible ducting can also reduce air leakage, noise, and energy loss, as well as improve indoor air quality and comfort.

In this article, we will explain what flexible ducting is, how it works, what are its benefits and drawbacks, and how to choose and install the right flexible ducts for your HVAC system. We will also introduce you to some of the best flexible ducting products available on the market, such as the black flexible ducting and the foil flexible ducting from Buy Insulation Online. By the end of this article, you will have a better understanding of flexible ducting and how it can enhance your HVAC system.

What is Flexible Ducting?

Flexible ducting is a type of ductwork that consists of a flexible inner core made of plastic or metal, surrounded by a layer of insulation, and covered by a protective outer jacket. Flexible ducting can be easily bent, twisted, and stretched to fit any shape or size of space, making it suitable for connecting the main ducts to the air outlets or registers. Flexible ducting can also be used as a standalone duct system in some cases, such as in small or temporary buildings.

Flexible ducting is a type of ductwork that consists of a flexible inner core made of plastic or metal, surrounded by a layer of insulation, and covered by a protective outer jacket. Flexible ducting can be easily bent, twisted, and stretched to fit any shape or size of space, making it suitable for connecting the main ducts to the air outlets or registers. Flexible ducting can also be used as a standalone duct system in some cases, such as in small or temporary buildings.

Flexible ducting comes in various sizes, shapes, materials, and designs, depending on the application and the requirements of the HVAC system. Some of the most common types of flexible ducting are:

- Black flexible ducting: This is a type of flexible ducting that has a black outer jacket made of polyethylene or polyester. Black flexible ducting is resistant to UV rays, moisture, chemicals, and abrasion, making it durable and long-lasting. Black flexible ducting is also easy to cut and install and can withstand high temperatures and pressures. Black flexible ducting is ideal for applications where aesthetics and durability are important, such as in commercial or industrial buildings.

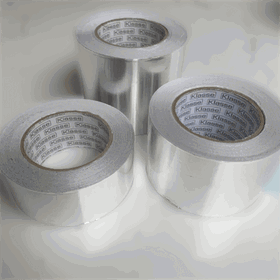

- Foil flexible ducting: This is a type of flexible ducting that has a metallic foil outer jacket made of aluminium or steel. Foil flexible ducting is reflective and shiny, making it attractive and eye-catching. Foil flexible ducting is also lightweight, flexible, and strong, and can handle high temperatures and pressures. Foil flexible ducting is ideal for applications where thermal performance and fire resistance are important, such as in residential or public buildings.

How Does Flexible Ducting Work?

Flexible ducting works by transporting the conditioned air from the HVAC unit to the air outlets or registers, where it is distributed to the different zones or rooms of the building. Flexible ducting can also return the air from the air inlets or grilles to the HVAC unit, where it is filtered and reconditioned. Flexible ducting can be connected to the main ducts or the HVAC unit using clamps, straps, tapes or screws. Flexible ducting can also be supported by hangers, brackets, or wires to prevent sagging or kinking.

Flexible ducting works by creating a low-resistance path for the airflow, allowing the HVAC unit to operate at optimal efficiency and performance. Flexible ducting can also reduce the noise and vibration caused by the airflow, as well as the heat loss or gain through the duct walls, improving indoor air quality and comfort. Flexible ducting can also adapt to the changes in the layout or design of the building, as well as the expansion or contraction of the ducts due to temperature or humidity fluctuations, ensuring a reliable and consistent air delivery.

What are the Benefits and Drawbacks of Flexible Ducting?

Flexible ducting has many benefits and drawbacks, depending on the type, quality and installation of the ducts. Some of the benefits and drawbacks of flexible ducting are:

Benefits:

- Flexible ducting is easy and quick to install, as it does not require any cutting, welding or soldering. Flexible ducting can also be installed in tight or hard-to-reach spaces, where rigid ducts would not fit.

- Flexible ducting is cost-effective, as it does not require any special tools, equipment, or labour. Flexible ducting can also save on material and energy costs, as it does not require any extra fittings, joints, or insulation.

- Flexible ducting is versatile, as it can be used for various applications and purposes, such as heating, cooling, ventilation, exhaust, dust collection, fume extraction, etc. Flexible ducting can also be used for different types of HVAC systems, such as split, central, ductless, etc.

- Flexible ducting is comfortable, as it can reduce the noise and vibration caused by the airflow, as well as the heat loss or gain through the duct walls, improving the indoor air quality and comfort. Flexible ducting can also prevent condensation, mould, and mildew growth, as well as pest and rodent infestation, enhancing the health and safety of the occupants.

Drawbacks:

- Flexible ducting is prone to damage, as it can be easily punctured, torn, or ripped by sharp objects, animals, or human activities. Flexible ducting can also deteriorate over time, due to exposure to UV rays, moisture, chemicals, or abrasion, reducing its lifespan and performance.

- Flexible ducting is susceptible to air leakage, as it can have gaps, holes or cracks at the connections, joints, or seams. Flexible ducting can also have bends, twists or kinks that can restrict or obstruct the airflow, increasing the resistance and pressure. Flexible ducting can also sag or collapse due to improper support or installation, affecting air delivery and distribution.

- Flexible ducting is difficult to clean, as it can have dust, dirt, or debris accumulation inside the ducts, reducing the air quality and efficiency. Flexible ducting can also have microbial or fungal growth inside the ducts, causing odours, allergies, or infections. Flexible ducting can also have fire or smoke hazards, as it can ignite or melt due to high temperatures or sparks.

How to Choose and Install the Right Flexible Ducts for Your HVAC System?

Choosing and installing the right flexible ducts for your HVAC system is crucial, as it can affect the performance, efficiency, and durability of your system, as well as the comfort, health and safety of your occupants. Here are some tips and guidelines on how to choose and install the right flexible ducts for your HVAC system:

- Choose the right size and length of flexible ducts for your HVAC system, based on the airflow, pressure and velocity requirements, as well as the layout and design of your space. You can use a duct sizing calculator or a duct sizing chart to determine the optimal size and length of flexible ducts for your system. You should also avoid using flexible ducts that are too long, as they can increase the resistance and pressure, reducing the efficiency and performance of your system.

- Choose the right type and material of flexible ducts for your HVAC system, based on the application and the environment of your space. You should consider the temperature, humidity, moisture, chemicals, UV rays, fire, smoke, and other factors that can affect the durability and performance of your flexible ducts. You should also choose flexible ducts that are compatible with your HVAC unit and your main ducts, as well as with the local codes and standards of your area.

- Choose the right insulation and protection for your flexible ducts, based on the thermal and acoustic requirements of your space. You should consider heat loss or gain, noise and vibration, condensation and mould, pests and rodents, and other factors that can affect the comfort and quality of your space. You should also choose flexible ducts that have adequate insulation and protection, such as R-value, vapour barrier, outer jacket, etc., to ensure optimal performance and durability of your flexible ducts.

- Install your flexible ducts properly and securely, following the manufacturer’s instructions and the best practices of the industry. You should use the appropriate tools, equipment, and accessories, such as clamps, straps, tapes, or screws, to connect and fasten your flexible ducts to your HVAC unit and your main ducts. You should also use the proper support and suspension, such as hangers, brackets, or wires, to prevent sagging or kinking of your flexible ducts. You should also avoid any sharp bends, twists or kinks that can restrict or obstruct the airflow, as well as any gaps, holes or cracks that can cause air leakage, in your flexible ducts. You should also inspect and test your flexible ducts regularly, to ensure they are working properly and efficiently.

What are the Best Flexible Ducting Products Available on the Market?

If you are looking for the best flexible ducting products available on the market, you might want to check out the black flexible ducting and the foil flexible ducting from our website Buy Insulation Online. These are high-quality and affordable flexible ducting products that can suit any HVAC system and any space. Here are some of the features and benefits of these flexible ducting products:

If you are looking for the best flexible ducting products available on the market, you might want to check out the black flexible ducting and the foil flexible ducting from our website Buy Insulation Online. These are high-quality and affordable flexible ducting products that can suit any HVAC system and any space. Here are some of the features and benefits of these flexible ducting products:

- Black flexible ducting: This is a type of flexible ducting that has a black outer jacket made of polyethylene or polyester. Black flexible ducting is resistant to UV rays, moisture, chemicals, and abrasion, making it durable and long-lasting. Black flexible ducting is also easy to cut and install and can withstand high temperatures and pressures. Black flexible ducting is ideal for applications where aesthetics and durability are important, such as in commercial or industrial buildings. Black flexible ducting is available in various sizes, ranging from 80mm to 400mm in diameter, and various lengths, ranging from 3m to 10m.

- Foil flexible ducting: This is a type of flexible ducting that has a metallic foil outer jacket made of aluminium or steel. Foil flexible ducting is reflective and shiny, making it attractive and eye-catching. Foil flexible ducting is also lightweight, flexible, and strong, and can handle high temperatures and pressures. Foil flexible ducting is ideal for applications where thermal performance and fire resistance are important, such as in residential or public buildings. Foil flexible ducting is available in various sizes, ranging from 80mm to 400mm in diameter, and various lengths, ranging from 3m to 10m.

Both black flexible ducting and foil flexible ducting from Buy Insulation Online have a flexible inner core made of galvanised steel wire helix, surrounded by a layer of glass wool insulation, and covered by a protective outer jacket. Both flexible ducting products have an R-value of 1.0, which means they have good thermal resistance and can prevent heat loss or gain through the duct walls. Both flexible ducting products also have a vapour barrier, which means they can prevent moisture and condensation from forming inside the ducts. Both flexible ducting products also have a fire rating of Class 0, which means they are non-combustible and can resist fire and smoke.

You can order these flexible ducting products online from our website Buy Insulation Online, we are the leading online supplier of insulation and building materials in the UK. You can also browse our website for more information and details about our flexible ducting products, as well as our other products and services. You can also contact our friendly and helpful customer service team, who can assist you with any queries or issues you might have.

Benefits and Applications of Insulated Flexible Ducting

Insulated flexible ducting offers several advantages in various applications. Primarily, its insulation properties help prevent condensation buildup, reducing the risk of moisture-related issues within HVAC systems. By mitigating condensation, it maintains the integrity of the ducting and prevents potential damage, ensuring longevity.

Moreover, its insulation capabilities aid in minimizing heat loss or gain, contributing to enhanced energy efficiency. This aspect not only reduces operational costs but also ensures consistent airflow and temperature control within the HVAC system. As a result, insulated flexible ducting significantly enhances overall system performance and comfort levels for both residential and commercial settings.

Flexible ducting finds wide-ranging applications across different sectors. It serves as a crucial component in ventilation systems for residential, commercial, and industrial buildings, effectively distributing air while maintaining flexibility for installation in various spaces.

Furthermore, it plays a pivotal role in HVAC systems, facilitating extraction, and efficient air distribution. Its adaptability and efficiency make it a preferred choice in applications that require the flow of air in a flexible and reliable manner.

Differentiating Between PVC and Aluminum Flexible Ducting

When considering flexible ducting options, understanding the distinctions between PVC and aluminium variants is crucial. PVC flexible ducting stands out for its corrosion and moisture resistance, making it suitable for environments where these factors pose significant challenges.

Conversely, aluminium flexible ducting, known for its lightweight nature and durability, offers ease of installation and flexibility. Choosing between the two depends on specific environmental conditions and project requirements. PVC suits moisture-prone areas, while aluminium proves advantageous for its flexibility and easy handling during installation.

Insulating Flexible Ducting for Efficiency

To enhance the insulation properties of flexible ducting, employing insulation sleeves or wraps made of materials like fibreglass or foam is recommended. These insulating materials act as barriers, preventing heat loss and condensation.

By maintaining efficient airflow and temperature control, the insulation safeguards the overall performance of the HVAC system during air distribution, contributing to energy efficiency and reduced operational costs. Properly insulating flexible ducting ensures optimal functionality, longevity, and minimal maintenance requirements for the entire HVAC system.

Conclusion

Flexible ducting is a great option for improving the efficiency and performance of your HVAC system, as well as the comfort and quality of your space. Flexible ducting can bend and twist to fit any space, making it ideal for complex or irregular layouts. Flexible ducting can also reduce air leakage, noise, and energy loss, as well as improve indoor air quality and comfort. Flexible ducting can also adapt to the changes in the layout or design of the building, as well as the expansion or contraction of the ducts due to temperature or humidity fluctuations, ensuring a reliable and consistent air delivery.

However, flexible ducting also has some drawbacks, such as being prone to damage, susceptible to air leakage, and difficult to clean. Therefore, you need to choose and install the right flexible ducts for your HVAC system, based on the airflow, pressure and velocity requirements, as well as the application and the environment of your space. You also need to choose and install the right insulation and protection for your flexible ducts, based on the thermal and acoustic requirements of your space. You also need to install your flexible ducts properly and securely, following the manufacturer’s instructions and the best practices of the industry.

If you are looking for the best flexible ducting products available on the market, you might want to check out the black flexible ducting and the foil flexible ducting from our website Buy Insulation Online. These are high-quality and affordable flexible ducting products that can suit any HVAC system and any space. You can order these flexible ducting products online from our website Buy Insulation Online, we are the leading online supplier of insulation and building materials in the UK.

Frequently Asked Questions

Q: What is flexible ducting?

A: Flexible ducting, also known as flexible hose or ducting pipe, is a type of ducting used for ventilation and air distribution in HVAC systems. It is designed to be flexible and versatile, allowing it to be easily routed around obstacles and through tight spaces.

Q: What are the common materials used in flexible ducting?

A: Common materials used in flexible ducting include aluminium, PVC, and PVC-coated materials. Aluminium flexible ducting is known for its durability and lightweight properties, while PVC and PVC-coated ducting are often used for their resistance to corrosion and moisture.

Q: What are the typical sizes available for flexible ducting?

A: Flexible ducting is available in various sizes, including 100mm, 125mm, 150mm, and 200mm diameters. These sizes cater to different ventilation and air distribution needs, allowing for customized installations based on the specific requirements of the HVAC system.

Q: What are the key factors to consider when choosing flexible ducting?

A: When choosing flexible ducting, it is important to consider factors such as the material of the ducting, the size and diameter required, the level of insulation needed, and the compatibility with the existing ventilation system. Additionally, considering the presence of any acoustic requirements is also crucial in certain applications.

Q: How is flexible ducting installed?

A: Flexible ducting is typically installed by connecting it to the ventilation system using appropriate connectors and fittings. It should be properly supported and insulated to ensure efficient air flow and minimize heat loss. Installation should be carried out in accordance with relevant regulations and guidelines.