Trace Heating Thermostats

Our range includes electronic thermostats, sensing thermostats, and controllers designed to monitor and control heat output in various applications. From simple frost protection to advanced temperature monitoring, each unit integrates seamlessly with trace heating cables and kits for easy installation. Ideal for both residential and industrial use, these products provide reliable protection in cold environments.

Explore our selection of trace heating thermostats and find the right control solution to enhance your trace heating system. With fast UK delivery and trusted brands, we help ensure your pipes stay protected throughout the winter months.

Similar Categories

Trace Heating Thermostats: The Essential Component for Efficient Temperature Control in the UK

Trace heating thermostats are crucial for ensuring the efficiency and reliability of trace heating systems in both domestic and industrial applications. Designed to provide accurate temperature control, these thermostats prevent pipes from freezing, maintain temperature levels, and enhance the performance of frost protection systems. This guide delves into the benefits, types, and key features of trace heating thermostats, focusing on their importance for UK installations.

What is a Trace Heating Thermostat?

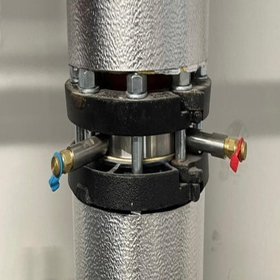

A trace heating thermostat is a temperature controller used in heat tracing systems to regulate the operation of heating cables. By monitoring ambient or pipe temperatures, the thermostat ensures the system operates only when required, thereby saving energy and preventing damage caused by freezing or overheating. These devices are suitable for both commercial and industrial heating applications.

Key Features of Trace Heating Thermostats

-

Accurate Temperature Control: Trace heating thermostats provide precise control, ensuring the heating system maintains the desired temperature efficiently.

-

Built-in Thermostat Options: Many frost protection trace heating kits include built-in thermostats, simplifying installation and reducing the need for additional components.

-

Digital and Manual Options: Digital trace heating thermostats offer advanced features such as programmable settings and alarm functions, while manual thermostats provide a straightforward and cost-effective solution.

-

Durability: These thermostats are built with robust materials like aluminium or polyethylene to withstand harsh conditions, ensuring reliable performance in external installations.

-

Alarm Systems: Integrated alarms notify users of faults or circuit issues, allowing for timely maintenance.

Benefits of Using Trace Heating Thermostats

-

Energy Efficiency: The thermostat ensures the trace heating system only operates when required to stop pipes freezing, reducing unnecessary energy consumption.

-

Damage Prevention: By preventing pipes from freezing, thermostats protect plumbing systems from damage caused by low temperatures.

-

Ease of Installation: Pre-made trace heating kits with built-in thermostats simplify the installation process, saving time and effort.

-

Versatility: Suitable for various heating applications, including frost protection, temperature maintenance, and heat tracing in commercial and industrial settings.

-

Reliability: High-quality thermostats are designed to function accurately in extreme conditions, ensuring consistent performance over time.

Types of Trace Heating Thermostats

-

Ambient Sensing Thermostats: These devices monitor the surrounding air temperature, making them ideal for applications where environmental conditions significantly impact performance.

-

Pipe Sensing Thermostats: These thermostats measure the pipe temperature directly, ensuring precise control for frost protection and temperature maintenance.

-

Digital Thermostats: Advanced options with programmable settings, relay outputs, and alarm systems for enhanced functionality.

-

Pre-Made Kits with Thermostats: Frost protection kits come with pre-terminated heating cables and built-in thermostats, offering a complete solution for quick and easy installation.

Applications of Trace Heating Thermostats

1. Domestic Use:

-

Protecting external pipes from freezing during winter.

-

Maintaining hot water temperature in residential systems.

2. Commercial and Industrial Applications:

-

Preventing damage to critical pipework in factories and warehouses.

-

Ensuring consistent temperatures for chemical or food processing.

3. HVAC Systems:

-

Regulating temperature for air conditioning and heating systems.

-

Providing efficient heat tracing for ductwork and ventilation.

How to Install a Trace Heating Thermostat

-

Select the Right Thermostat: Choose a thermostat suitable for your heating application, whether it’s ambient sensing, pipe sensing, or digital.

-

Prepare the System: Ensure the heating cable and pipe are clean and securely fixed using cable ties and fixing tapes.

-

Mount the Thermostat: Install the thermostat in a location that allows easy access and accurate temperature monitoring.

-

Connect the Sensor: Attach the sensor to the pipe or ambient area, depending on the thermostat type.

-

Test the System: Activate the thermostat and ensure it operates correctly, adjusting the settings as needed.

Recommended Trace Heating Thermostats

-

Trace Heating Kit with Thermostat: Pre-made kits featuring self-regulating heating cables and built-in thermostats, ideal for frost protection and temperature maintenance.

-

Digital Temperature Controllers: Advanced options for precise control and monitoring, suitable for industrial applications.

-

Raychem Products: High-performance thermostats designed for reliability in extreme conditions.

Conclusion

Trace heating thermostats are a critical component for maintaining efficient and reliable heating systems in the UK. Whether you’re protecting pipes from freezing or maintaining precise temperatures in industrial applications, a high-quality thermostat ensures optimal performance. Explore the range of trace heating thermostats and kits online to find the ideal solution for your needs.