Similar Categories

Valve Insulation Jackets: The Ultimate Guide for the UK Market

Introduction to Valve Insulation Jackets

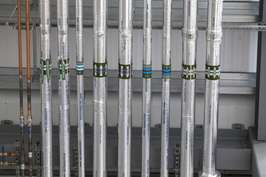

Valve insulation jackets are essential components in enhancing energy efficiency and providing thermal insulation for industrial and commercial pipework systems. Whether you're looking to reduce heat loss, protect personnel, or improve system performance, these jackets are a cost-effective solution suitable for applications across the UK.

What Are Valve Insulation Jackets?

Valve insulation jackets are flexible, removable insulation jackets designed to insulate pipe and valve systems. Unlike fixed insulation systems, these jackets can be easily fitted and removed, making them ideal for maintenance access. They are commonly made from silicone-coated glass fibre cloth with an infill of 50mm of mineral wool insulation, offering excellent thermal and acoustic insulation properties.

Key Features and Benefits

-

Energy Savings: Reduce heat loss and improve energy efficiency in thermal systems.

-

Personnel Protection: Prevent burns from the hot surface of the valve, creating a safer working environment.

-

Flexible and Removable: Jackets are designed to be easily removable, making maintenance straightforward.

-

Custom-Made Fit: Jackets are custom-made to fit specific valve shapes and sizes, ensuring maximum coverage.

-

Weather Resistant: Designed to withstand extreme temperatures and harsh environments.

Types of Valve Insulation Jackets

-

Removable Valve Insulation Jackets

Perfect for maintenance-heavy environments, allowing for easy removal and reinstallation. -

Flexible Valve Insulation Covers

Adaptable to various valve types, providing comprehensive thermal insulation. -

High Temperature Insulation Jackets

Suitable for extreme temperatures, offering superior thermal conductivity control. -

Anti-Freeze Valve Covers

Protect valves from freezing in low temperatures, ensuring system reliability.

How to Install Valve Insulation Jackets

-

Wrap It Around the Valve: Place the jacket over the valve, ensuring full coverage.

-

Secure with Velcro Straps: Use velcro straps that secure the jacket firmly in place.

-

Pull Cords and Straps: Tighten the pull cords that run along the length of the jacket for a snug fit.

-

Seal Edges: Take the velcro flaps and press them down to seal the insulation, preventing heat loss and condensation.

Applications of Valve Insulation Jackets

-

Industrial Pipework Systems

-

Commercial Heating Systems

-

HVAC Units

-

Energy Plants

-

Anti-Freeze Protection for Outdoor Valves

Materials Used in Valve Insulation Jackets

-

Mineral Wool Insulation: Offers excellent thermal performance with an infill of 50mm.

-

Glass Fibre Cloth: Provides durability and resistance to damage caused by extreme conditions.

-

Silicone-Coated Outer Layer: Ensures resistance to water, chemicals, and UV exposure.

Why Choose Valve Insulation Jackets?

-

Energy Efficiency: Minimise heat loss, reducing energy costs.

-

Improved Safety: Protect personnel from burns and prevent condensation from forming.

-

Versatility: Jackets are available in a range of colours and sizes, suitable for various applications.

-

Low Maintenance: Less likely to sustain damage compared to hard insulation options.

Additional Information

-

Delivery: Orders may incur a delivery charge, depending on location.

-

Custom Orders: Jackets are made to order to ensure a perfect fit for your valves.

-

Related Products: Pipe insulation jackets, thermal jackets, and acoustic insulation accessories are also available.

Conclusion

For effective thermal insulation and energy savings, valve insulation jackets are the ideal solution. Their flexible insulation covers, easy-to-fit design, and durable materials make them a smart choice for both industrial and commercial applications. Whether for anti-freeze protection or high-temperature environments, these jackets provide superior performance, making them an essential part of your insulation system.