Similar Categories

Pressure Reducing Valve Jacket Insulation: Maximising Efficiency & Cost Savings

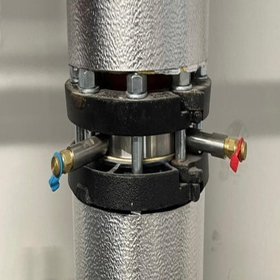

In industrial and commercial settings, pressure reducing valves (PRVs) play a crucial role in managing water and steam pressure. However, without proper insulation, they can lead to significant energy losses. Installing a valve insulation jacket is a cost-effective way to reduce energy costs, improve efficiency, and create a safer working environment.

Why PRVs Require Insulation?

PRVs, like other gate valves and water valves, experience heat loss when left uninsulated. A valve jacket insulation solution helps in reducing energy wastage, improving thermal conductivity, and maintaining system performance. These insulation jackets provide a protective layer that prevents heat dissipation and enhances overall insulation performance.

Benefits of Valve Jacket Insulation

-

Energy Efficiency & Cost Savings

-

Installing removable insulation jackets significantly contributes to reducing energy costs by preventing heat loss.

-

Insulated valve jackets help insulate and protect components, maintaining stable temperature levels.

-

-

Protection & Safety

-

PRVs and steam valves operate at high temperatures. Thermal insulation jackets provide an added layer of protection, preventing accidental burns and maintaining a cooler and safer workspace.

-

They also ensure airtight insulation, which is crucial for operational efficiency.

-

-

Custom Fit & Easy Installation

-

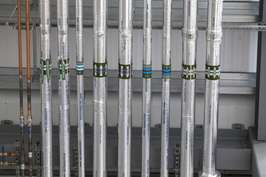

Insulation jackets are custom-made for each specific valve, ensuring a proper fit around internal valve components.

-

Jackets are designed to be easily removable, making maintenance simple without compromising on insulation.

-

Various fastening options like Velcro straps and pull cords allow for quick removal and reinstallation.

-

Types of Valve Jacket Insulation Available in the UK

-

Standard Insulation Jackets

-

Suitable for a whole variety of pipe fittings, including steam pressure-reducing valves, heat exchangers, and pressure regulators.

-

Available in different insulation thickness levels to suit various temperature requirements.

-

-

Custom-Made Valve Jackets

-

Jackets are available in bespoke requirements, ensuring a specific application for each actual valve.

-

Designed with fibreglass cloth and hard insulation for superior insulation properties.

-

-

Fixed & Removable Insulation Jackets

-

Fixed insulation is ideal for permanent solutions, while removable insulation offers flexibility for maintenance and adjustments.

-

Removable insulation jackets are designed for PRVs and other external valve applications.

-

Installation Process: How to Insulate PRVs Effectively

-

Choose the Right Jacket

-

Work with a trusted insulation online supplier to find a valve cover that fits your specific valve and temperature range.

-

-

Install the Valve Insulation Jacket

-

Ensure a proper fit around the internal valve to achieve airtight insulation.

-

Secure using Velcro straps or pull cords for easy access.

-

-

Maintain & Inspect Regularly

-

Periodically check the insulation for wear and tear to maintain insulation performance.

-

Replace or upgrade as needed to ensure cost savings and energy efficiency.

-