Please note: All Valve jackets are made to order, No returns, refunds or exchanges will be applicable. If you are unsure of the size/type of jacket, please email us a picture of the valve and we can advise accordingly, before placing the order. We will assist you in any way we can.

Flange covers are perhaps one of the best and most innovative ways to insulate blank-end flanges. We believe that they perform far better than the traditional rigid wool insulation used to insulate valves, and here is why:

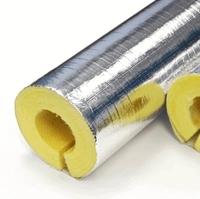

Their make: The flange covers are made with the finest quality silicone glass cloth. We use 50mm Rockwool for insulation.

Thermal Insulation: The mineral wool insulation used for insulating has a low thermal conductivity and hence will prevent heat loss from flange end-caps. So insulated valve jackets help save energy and money. This is especially important in commercial and industrial environments.

Easy Installation and Maintenance: Flanges are crucial points of connection in piping systems. They need to be well maintained. Flange covers help you do just that. They make maintenance easier and reduce the time required. Uninstall the valve covers by removing the velcro straps and loosening the pull cords. Valve jackets are be re-installed just as easily. The valve covers can be removed with no harm done to the insulation or the pipework, unlike rigid wool insulation.

Safer Workplace: Flange covers protect your workforce from hot surfaces of flange end-caps, making the workplace safer. They also minimise any external damage to the flange end-caps. Due to their insulating properties, they reduce condensation and sweating in flanges. They hence reduce the formation of tiny pools of water in the workplace. This helps prevent accidents and slips and falls.

Moisture Protection: When used externally valve covers for flange end-caps are made with a waterproof PVC material which protects these valves not only from moisture ingress but also from external damages.

Product Specification:

- Product Sizes: 15mm, 20mm, 25mm, 32mm, 40mm, 50mm, 65mm, 80mm, 100mm, 125mm, 150mm, 200mm, 250mm, 300mm, 350mm, 400mm, 450mm and 500mm.

- Colours: Standard grey, Silver (foil) and standard black.

- Service Temperature: -20 °C to +220 °C

- Insulation: 50mm Rockwool

- Type:

- External jackets - These are made with silicone glass cloth on the inner side and waterproof PVC on the outside

- Internal jackets - Valve covers for internal applications have silicone glass cloth on both the sides.

Key Features:

- Flange covers provide effective thermal insulation around flange union valves.

- They are lightweight, easy to use, handle and install.

- Valve jackets provide fully sealed insulation to avoid any airborne contamination and possible harm to personnel.

- Flange covers help reduce energy bills.

- Their velcro flaps and pull cords ensure a perfect fit around the flanges

- They are cost-effective and convenient.

- Valve jackets protect the valves from dirt, dust and rust.

- They improve workplace safety by reducing the heat emitted by the surface

- Flange covers are made from silicone glass fibre cloth sewn with around 50mm of insulation.

Applications:

- Valve jackets are designed to closely fit around awkward flange end-caps to maximise insulation and remove possible sharp edge hazards.

Note:

- All Valve jackets are made to order, No returns, refunds or exchanges will be applicable. If you are unsure of the size, please email us a picture of the valve and its dimensions for our experts to access and make the valve covers suitable for your application. We will assist you in any way we can.

- Lead times for screwed valve covers within the UK: 1-10 units: 5-7 working days, Anything above that, please email us for the lead times.

- Flange covers for end-caps are available in sizes ranging from 1/2 inch to 12 inches.

- You can also choose from standard grey, silver and standard black

- They give a neat and professional finish to flange end-caps.

- Flange covers are made with the highest quality silicone glass cloth.

- They are lightweight, easy to use and install.

- Thermal insulation jackets give superior insulation around flanges and prevent heat loss.

- Valve jackets provide effective insulation in temperatures ranging from -20 °C to +220 °C

- Flange covers increase workplace safety and reduce maintenance time by half.

- All valve covers are made to order and NON REFUNDABLE

| Insulation Type | Flange Covers |

| Cloth Material | Silicone glass or PVC cloth |

| Insulation | Mineral Wool |

| Suitable for | Flange end-caps |

| Colours Available | Standard Black, Silver and Standard Grey |

| Standard Sizes |

15mm, 20mm, 25mm, 32mm, 40mm, 50mm, 65mm, 80mm, 100mm, 125mm, 150mm, 200mm, 250mm, 300mm, 350mm, 400mm, 450mm and 500mm. |

| Service Temperature |

-20 °C to +220 °C |

| Delivery Terms | |

|---|---|

| All Orders £20 +VAT |

Product: All valve covers are made to order and NON-REFUNDABLE. If you are unsure of the size, please email us a picture of the valve and its dimensions for our experts to access and make the valve covers suitable for your application. We will assist you in any way we can.

We welcome you to share information on the pipe insulation thickness and images of your application along with the order to help us get your requirement correctly.

If you require a quote for these valve jackets, please email us with your requirements

Returns and cancellations:

You are free to cancel your order before we confirm your order via email. Once an order confirmation email is sent, cancellations, returns and refunds will not be acceptable.

Additional information:

- We do site surveys and supply valve covers or we can only survey your premises. If you would like a site survey, kindly email us your site address or fill the contact form above.

- The prices for the chilled/cold water valve jackets may differ from those on the website. Chilled/cold water valves usually need to be wrapped with a vapour barrier, which would increase the jacket size and cost. If you need chilled/cold water valve covers, please mail us your requirements and we will send you a quote for your order.

- We also make valve covers in red, blue and green colours. If you have any such requirements, please get in touch with us.

When looking to improve energy efficiency and safeguard machinery, consider blank end flange insulation jackets. They diminish heat loss, prevent corrosion, and enhance workplace safety. These jackets, crafted from silicone-coated glass cloth, offer durability and excellent thermal properties. For installation, measure accurately, keep surfaces clean, and follow provided guidelines. Customization for different pipe sizes guarantees a snug fit. These jackets decrease energy consumption, lower bills, and increase sustainability. They're constructed to withstand harsh conditions and offer long-term protection. Regular maintenance and cleaning guarantee peak performance. Discover more about the benefits and applications of these insulation jackets.

Key Takeaways

- Reduce heat loss and prevent corrosion effectively.

- Ensure longevity and durability in industrial settings.

- Offer customization options for various pipe sizes.

- Enhance thermal efficiency and energy savings.

- Easy maintenance and cost-effectiveness for long-term savings.

Benefits of Blank End Flange Insulation Jackets

By using blank end flange insulation jackets, you can significantly reduce heat loss, prevent corrosion, and increase energy efficiency. These flange insulation benefits not only help in maintaining a vital working environment but also contribute to the overall efficiency of your equipment. The end flange advantages extend beyond just insulation; they also play an essential role in extending the lifespan of your machinery and guaranteeing workplace safety.

The customizable sizes of these jackets make them suitable for various applications, providing a tailored solution for your specific needs. Constructed with high-quality silicone glass cloth, these jackets offer durability that withstands the test of time. Additionally, the weatherproof feature ensures that they can be used in diverse environmental conditions without any degradation in performance.

With options available in standard grey, silver, and black colors, these jackets not only serve a functional purpose but also add a neat finish to your equipment, enhancing the overall aesthetics of your workspace.

Materials Used in Insulation Jackets

When it comes to insulation jackets, the materials used play an essential role in their effectiveness.

Jacket material options like silicone-coated glass cloth are known for their durability and resistance to heat, making them ideal for various industrial applications.

Jacket Material Options

When selecting jacket material options for insulation jackets, prioritize durability and thermal performance to meet the demands of industrial applications. Manufacturers often offer customization benefits, allowing you to tailor the jacket materials to your specific needs.

Performance comparison is key when deciding on the best jacket material option. Silicone-coated glass cloth stands out as a popular choice due to its excellent thermal properties and longevity. This material is known for being durable, weatherproof, and resistant to wear and tear, making it ideal for withstanding high temperatures in various industrial settings.

Insulation Jacket Durability

Constructed with high-quality silicone glass cloth for durability, the materials used in Blank End Flange Insulation Jackets guarantee long-lasting insulation and resistance to wear and tear in industrial applications.

These jackets are designed to withstand high temperatures, providing exceptional heat retention and extending the insulation lifespan. The durability of the insulation jackets ensures they maintain their effectiveness in preventing heat loss and corrosion.

The high-quality materials used make these jackets a reliable solution for various industrial applications, giving you peace of mind knowing that your equipment is well-insulated and protected.

Installation Process for Flange Jackets

To guarantee a successful installation of Blank End Flange Insulation Jackets, start by accurately measuring the flange size. Proper sizing is essential to make certain the insulation jacket fits snugly around the flange.

Before applying the jacket, make sure the surface is clean and dry for best performance. Use the provided fasteners such as Velcro flaps and pull cords to secure the jacket tightly around the flange.

It's vital to verify that the insulation jacket covers the entire flange end to prevent heat loss effectively. Following the manufacturer's guidelines and recommendations is key to a proper and secure installation of the flange jacket.

Customization Options for Pipe Sizes

For a tailored fit on various pipe sizes, consider the customization options available for Blank End Flange Insulation Jackets. When selecting the right size for your insulation needs, you can benefit from the following:

- Pipe customization: Options available for pipe sizes ranging from 1/2 inch to 12 inches allow you to find the perfect fit for your specific pipes.

- Size selection: Choose from various size options such as 1/2 Inch (15mm), 3/4 Inch (20mm), 1 Inch (25mm), and beyond to guarantee a precise fit.

- Tailored solutions: With flexible sizing choices for different pipe diameters including 1 1/4 Inch (32mm), 1 1/2 Inch (40mm), and more, you can customize your insulation jacket to match your unique requirements.

These customizable features guarantee that your Blank End Flange Insulation Jackets will provide a snug and effective fit on pipes, valves, flanges, tanks, and heat exchangers, meeting your insulation needs perfectly.

Thermal Efficiency and Energy Savings

End Flange Insulation Jackets offer significant energy efficiency benefits. They help you decrease heat loss and lower energy bills. By providing thermal insulation for end-caps, these jackets contribute to cost-saving advantages in the long run.

Embracing this solution not only improves thermal efficiency but also supports your bottom line through reduced energy consumption.

Energy Efficiency Benefits

Improving energy efficiency and saving costs are key benefits of utilizing Blank End Flange Insulation Jackets. These jackets aid in energy conservation by reducing heat loss and enhancing heat retention. By incorporating Blank End Flange Insulation Jackets, you can experience the following advantages:

- Decreased Energy Consumption: The thermal insulation provided by these jackets helps in maintaining ideal temperatures, reducing the need for constant heating or cooling.

- Lower Energy Bills: With improved thermal efficiency, you can expect to see a decrease in energy usage, leading to cost savings on your utility bills.

- Enhanced Sustainability: Utilizing these insulation jackets aligns with sustainability goals by cutting down on greenhouse gas emissions and promoting energy efficiency practices.

Cost-Saving Advantages

Using Blank End Flange Insulation Jackets can result in significant cost savings through improved thermal efficiency and reduced energy consumption. These jackets offer installation benefits by easily fitting over end flanges, providing a hassle-free solution for boosting insulation.

The upgraded thermal efficiency not only lowers energy bills but also leads to long-term savings by reducing maintenance and replacement expenses. By investing in Blank End Flange Insulation Jackets, you're making a cost-effective choice that improves energy efficiency and decreases operational costs.

Additionally, the use of these jackets contributes to a more sustainable environment by lowering your carbon footprint and ensuring compliance with environmental regulations. Embrace the advantages of these insulation jackets to enjoy both immediate savings and long-lasting benefits.

Industrial Applications of Insulation Jackets

Insulation jackets find wide application across various industrial sectors for their ability to improve energy efficiency and prevent heat loss. In industrial maintenance, these jackets play an essential role in preserving equipment and preventing heat loss in pipes, valves, and tanks.

Temperature regulation is another key benefit, ensuring ideal operating conditions for machinery and processes. Additionally, insulation jackets help in enhancing workplace safety by maintaining consistent temperatures and reducing the risk of accidents.

These jackets are cost-effective solutions that not only save energy but also extend the lifespan of equipment. With customizable sizes, high-temperature resistance, and durable materials, insulation jackets are suitable for a wide range of industrial applications, making them a versatile and essential asset in various industries.

Commercial Uses for Flange Insulation

Improving energy efficiency and preventing heat loss in commercial settings, flange insulation jackets are a valuable asset for various industries. These jackets find extensive use in commercial applications such as insulating pipes, valves, tanks, and heat exchangers. By incorporating flange insulation jackets, businesses can reduce the risk of corrosion, extend equipment lifespan, and enhance workplace safety. Additionally, these jackets can be customized to fit different sizes and offer high-temperature resistance, making them versatile for a wide range of commercial needs.

When it comes to maintenance procedures, flange insulation jackets simplify upkeep tasks, reducing the need for frequent repairs and replacements. This not only saves time but also lowers maintenance costs, providing businesses with long-term benefits. Additionally, by using flange insulation jackets, companies can comply with environmental regulations, minimizing their carbon footprint and contributing to sustainability efforts. Overall, the commercial uses of flange insulation jackets offer significant advantages in terms of efficiency, cost savings, and environmental impact.

Durability and Longevity of Jackets

Constructed with high-quality silicone glass cloth, Blank End Flange Insulation Jackets guarantee durability and longevity in industrial settings. These jackets offer long-term performance, ensuring reliable protection against heat loss, corrosion, and other environmental factors.

Designed to withstand high temperatures and harsh industrial conditions, they provide sustainable insulation that remains effective over time. The durable materials used in these jackets ensure a long lifespan, reducing the need for frequent replacements and maintenance.

Investing in Blank End Flange Insulation Jackets not only assures the longevity of the insulation covers but also leads to cost savings in the long run. With their reliability and effectiveness in maintaining insulation, these jackets are a valuable asset for industrial facilities looking for durable solutions that stand the test of time.

Maintenance Tips for Insulation Covers

When maintaining insulation covers, remember to check for signs of wear and tear regularly.

Cleaning the covers periodically and ensuring they're properly fitted will help prevent heat loss and maintain efficiency.

Keep an eye on the fasteners to confirm they're secure and follow manufacturer guidelines for best performance.

Cleaning Insulation Covers

To effectively maintain your insulation covers, regularly wipe them down with a damp cloth to remove dust and dirt buildup. When cleaning insulation covers, consider these helpful tips:

- Use mild soap and water: For stubborn stains, utilize a mixture of mild soap and water to gently clean the covers without saturating the insulation material.

- Inspect for tears and damage: Periodically check the covers for any tears, damage, or signs of wear and tear that could impact their effectiveness.

- Ensure ventilation: Maintain proper air circulation around the covers to prevent moisture buildup and inhibit the growth of mold.

Checking for Damage

Inspecting insulation covers regularly for any tears, rips, or signs of wear and tear is essential to maintain their performance and effectiveness. To help you assess the damage and find suitable repair solutions, consider the following table:

|

Damage Assessment |

Repair Solutions |

|

Tears or Rips |

Patch with insulation tape |

|

Discoloration |

Check for underlying issues |

|

Deformation |

Replace damaged sections |

|

Loose Fasteners |

Reattach or replace |

Preventing Heat Loss

To maintain peak performance and efficiency of your insulation covers, proactively preventing heat loss is crucial in prolonging their lifespan and reducing energy consumption. Here are some maintenance tips for your insulation covers:

- Regularly inspect for any signs of wear and tear on the insulation jackets.

- Guarantee a tight fit to prevent heat transfer and maintain thermal protection.

- Clean the covers periodically to remove any debris that may impact their insulating properties.

Cost-Effectiveness of Flange Insulation

Investing in flange insulation jackets offers significant cost-effectiveness through lowered energy bills, maintenance expenses, and long-term savings. These cost-efficient solutions not only help in reducing your financial burden but also play an important role in energy conservation.

By installing flange insulation covers, you can enjoy financial savings due to decreased heat loss, improved energy efficiency, and prolonged equipment durability. The initial investment in these jackets is affordable, leading to minimal replacement costs in the future.

Additionally, the environmental impact of using flange insulation jackets is substantial, contributing to a lower carbon footprint, reduced greenhouse gas emissions, and alignment with sustainability goals. Choosing flange insulation jackets isn't only a wise financial decision but also a responsible step towards protecting the environment.

Embrace these jackets to not only save money but also to be a part of the collective effort towards a greener and more sustainable future.

Frequently Asked Questions

How Warm Is 60 GSM Insulation?

When it comes to 60 GSM insulation, you'll find it offers moderate warmth, perfect for various activities. With good thermal efficiency and the option for layering, this type of insulation is great for outdoor adventures and everyday comfort.

How Many Grams of Insulation Do I Need for a Winter Coat?

To determine the insulation effectiveness for your winter coat, consider factors like desired warmth and activity level. Layering techniques can improve warmth. Understanding insulation weight, measured in gsm, helps you choose the right level for comfort.

What Does 80G Insulation Mean?

When you see 80g insulation, think about efficiency and warmth. This type of insulation is perfect for layering, keeping you cozy without bulk. It's like a snug hug, trapping heat and keeping you comfortable.

What Temperature Is 40G Insulation?

40g insulation is rated for temperatures up to 230 degrees Celsius, striking a balance between heat retention and flexibility. It offers thermal efficiency in various industrial settings, providing adequate insulation performance for maintaining temperature stability in equipment.